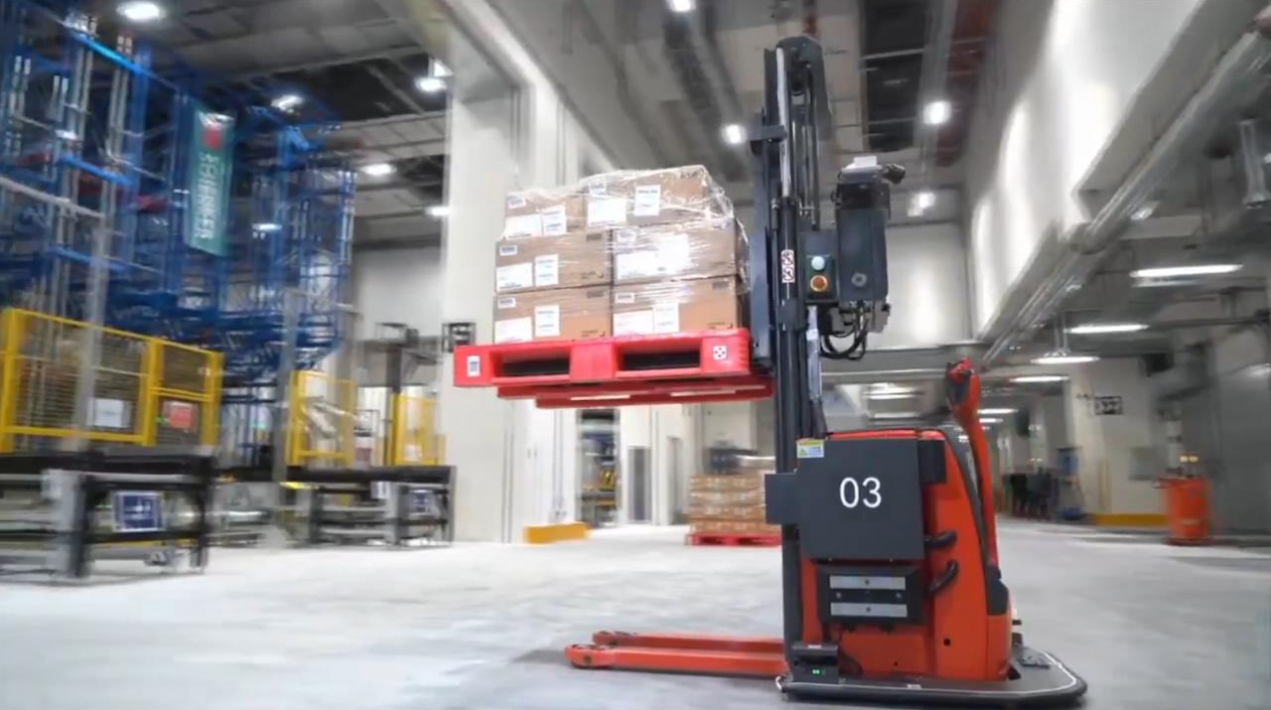

The Advanced Manufacturing Centre (AMC) in Tseung Kwan O INNOPARK is being provided with advanced robotics technology by a driverless industrial vehicle manufacturer, making it the first autonomous forklift supplier to provide advanced logistics automation services to support high-value “innofacturing” and long-term re-industrialisation.

The AMC logistics centre receives 24-hour core logistics services from the manufacturer. AMC is equipped with an array of automated robotics equipment including automated storage and retrieval system (mobile dense racks, four-way shuttles, automatic conveyors), automatic sorting arms and autonomous forklifts, which form the core equipment for transporting goods across AMC’s eight stories.

This project uses the company’s pallet stacking autonomous forklift vehicle which is equipped with a visual positioning module, high-precision sensing module and servo motion control module. This enables autonomous path planning, self-adjusting pick-up and automatic data interaction, making the transportation of products or goods seamless and efficient.

It currently supports multiple automated production lines in automotive, electrical and mechanical manufacturing industries. It is worth noting that the VNL14 is the first vehicle in the world which has been awarded a CE certificate by global testing service provider TÜV SÜD, based on the latest safety standard for driverless industrial vehicles, ISO 3691-4:2020.

The autonomous forklift trucks have been deployed on each floor in AMC to shift materials in and out, and through the 10 lifts on both sides of the building to achieve seamless logistics flow on each floor. Early on in the project, the company developed a 3-step implementation plan via onsite survey and mapping out the complete logistics process:

- The system will be docked to the user WCS and customised with the RCS (Robot Control System) function to connect the automated equipment and the autonomous forklifts for information integration and collaborative operation.

- For execution, highly efficient autonomous forklifts are deployed to coordinate with the RCS system to complete moving tasks;

- On safety, a multi-storey safety setup is deployed, with different tiers of safety principles and backup principles set from the terminal autonomous forklift to the top-level system.

An engineer from the manufacturer on-site stated that while approximately ten autonomous forklifts are deployed on the ground floor, the floor has limited space for operational movement. Goods are randomly delivered from different lifts, and then the autonomous forklifts enter the lifts to pick up the goods to transport them to the ASRS conveyor – adding to the high demands on the RCS system. In addition to information exchange and real-time interaction, scheduling was a major challenge.

It is necessary to constantly adjust the tiller wheels for steering or obstacle avoidance for under-actuated mobile robots like forklifts. This may cause multiple vehicles to lock up and interrupt the task in a limited space. The company’s scheduling algorithms were crucial in the project, achieving smooth and efficient material handling through task distribution, timing rescheduling and circumvention strategies.

The automation of AMC’s logistics has resulted in:

- Increased efficiency: Through the system interface, it realises cross-floor and multi-automated equipment synergy, and the efficiency of inbound and outbound storage on the ground floor exceeds 40 pallets/h, meeting the efficiency requirements.

- Greater digital management: Real-time information interaction of the whole process, realising the matching of information flow and logistics, creates the basis for digitalisation of intelligent logistics.

- Enhanced safety: In addition to the multi-level safety settings on both the vehicle side and system side, the company also features the latest UWB safety module to solve the safety problem of people entering the blind spot of autonomous forklift detection or sudden intrusion, avoiding the safety risk in advance and providing the highest level of protection for people.

HKSTP’s Head of Re-industrialisation noted that the Park is committed to promoting innofacturing by nurturing talent and providing resources and infrastructure support to emerging I&T ventures. Apart from the logistics services integrated with automation and advanced smart solutions provided by our partners, AMC is well-equipped with warehousing, prototyping, low-volume assembly support and cleanroom-enabled space to further support Innofacturing which helps advanced manufacturing companies to accelerate their R&D and production processes, thus enriching the entire I&T ecosystem.