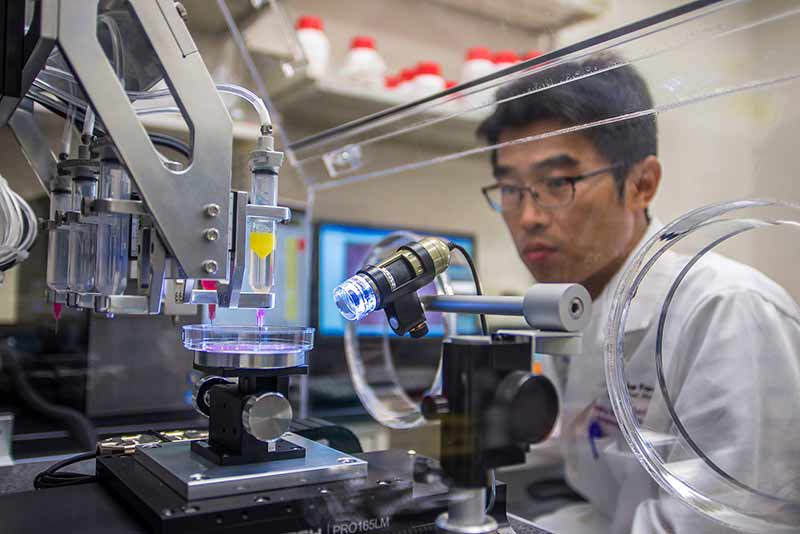

Bioprinting muscle tissue (Image credit: U.S. Army Materiel Command/ CC BY 2.0)

Yesterday the Dubai Health Authority announced that doctors had saved the life of a sixty-year-old Omani woman who suffered from a cerebral aneurysm, with assistance from a state-of-the-art custom 3D-printed model of the patient’s brain dilated arteries to help plan the complex surgery.

The patient was admitted to the hospital after suffering from severe bleeding in the brain. Due to the complexity and rarity of the patient’s case the doctors needed a 3D model that would allow them to understand exactly how to reach the arteries in a safe manner. Without the 3D model the surgery would have taken longer and the risk would have been higher.

This is not the first time that the Dubai Health Authority (DHA) had conducted a complex surgery with the aid of 3D printing. Last December, DHA’s doctors successfully removed a tumour from a patient’s kidney with the help of a custom 3D-printed organ to help plan the surgery. A Dubai resident recently received the region’s first-ever fully 3D-printed prosthetic leg, an innovation that could reduce the prices of prosthetics by 50%.

The DHA is planning to further utilise 3D printing in medical care in Dubai as it is in line with the Dubai 3D Printing Strategy.

Bioprinting

Healthcare is among the fields which could see significant impact from the emerging area of 3D printing or additive manufacturing (AM), ‘additive’ because the technology involves the sequential addition of material in layers, as directed by a 3D model. The 3D model could be designed in a software or created from the 3D scan of an object or from a series of photographs using photogrammetry.

The use of 3D printing techniques is being extensively explored for fabricating tissues and organs.

Organ-on-a-chip

Biomedical research and drug development is reliant on animal testing and conventional cell culture. Organs-on-chip could be used for testing drugs. They could enable researchers to eliminate ineffective drugs at an early stage of development, avoid the loss of animal lives and maybe provide more accurate results in the bargain, as animal physiologies offer only a rough approximation of human bodies.

They could even provide personalised drug screening platforms, as the organ-specific cells are usually created from pluripotent or multipotent stem cells, which are patient-specific ( Pluripotent cells can give rise to all of the cell types that make up the body; embryonic stem cells are considered pluripotent. Multipotent cells can develop into more than one cell type, but are more limited than pluripotent cells; adult stem cells and cord blood stem cells are considered multipotent.)

Models of liver, heart, lungs, kidneys on a chip have been engineered to mimic multiple complex physiological conditions or evaluate cell-to-cell interactions. They can be used for modeling reactions of the body to diseases.

These ‘organs’ are created using a combination of microchips and living human cells. The cells are introduced in the form in bioinks which are hydrogel (a gel composed usually of one or more polymers suspended in water, usually consisting of over 90% water) biomaterial that can be printed accurately onto a chip through a printing nozzle or needle. They need to maintain shape after deposition. They also have to maintain the viability of the cells blended within the bioinks during and after the printing process, otherwise the entire purpose is lost. Bioinks provide support to cells while they produce their own extracellular matrix. Ultimately cells reorganise themselves in a self-sufficient manner, there is no further need for supporting materials and a functional tissue is generated.

A common of concern with organs-on-chips lies is the isolation of organs during testing, which might lead to inaccurate results. To address this, efforts are ongoing to to develop human-on-a chip. For instance, researchers at the Wyss Institute for Biologically Inspired Engineering have developed an automated instrument to link multiple organs-on-chips together by their common vascular channels. This instrument, designed to mimic whole-body physiology, controls fluid flow and cell viability while permitting real-time observation of the cultured tissues. It offers the ability to analyse complex interconnected biochemical and physiological responses across ten different organs. The “human body-on-a-chip” approach can be used to quickly assess systemic responses to new drug candidates.

Body parts and organs for implantation

Organ printing could provide a potential solution for the global shortage of donor organs. However, organs or body parts that have been successfully printed and implemented in a clinical setting are either flat, such as skin, vascular, such as blood vessels, or hollow, such as the bladder.

More complex organs suitable to implant in human body cannot be printed yet.

Most of the organs described above lack crucial elements such as working blood vessels, tubules for collecting urine, and the growth of billions of cells required for these organs. We are some way off from creating a heart or liver which could replace a human organ. These 3D printed organs are ‘too unstable, too simple, or too small’ to implant in humans. (This report from Scientific American talks about how a team of scientists from the University of Pennsylvania and the Massachusetts Institute of Technology printed a dissolvable sugar mould of the vessels and then build up the appropriate cells around the mold, instead of printing an organ and its inner vessels all at once. Later, the mold is washed away, leaving behind structurally sound passageways that are able to stand up to the varying blood pressure levels found in the body.)

TechCrunch reported that scientists from Sweden’s Sahlgrenska Academy and Chalmers University of Technology have managed to succe

ssfully implant human cartilage cells in six-week-old baby mice. Though the process is some way off from becoming a viable alternative for reconstructive surgery, the potential is amazing.

Meanwhile, the use of 3D printing for producing dental crowns and bridges, instead of traditional wax modeling is well underway. A 3D scan is taken, instead of uncomfortable impressions, which is later transformed into a 3D model and sent to be 3D printed.

3D-printed skin has been developed for burn victims. 3D-printed prosthetics could bring down the time and costs of developing a customised limb and replacing it over the person’s lifetime. A group called e-NABLE is doing interesting work in the area of 3D printable, open source prosthetics. It is a network of volunteers from all over the world who are using their 3D printers to create free 3D printed hands and arms for those in need of an upper limb assistive device.

The U.S. hearing aid industry converted to 100% additive manufacturing in less than 500 days according to the Harvard Business Review. Way back in 2013, there were more than 10,000,000 3D printed hearing aids in circulation worldwide.

3D-printing is on the verge of transforming most of the areas mentioned above.

Printing drugs

3D-printed drugs could enable personalised medicine delivery, such as non-standard doses for children or the elderly. In April 2016, an epilepsy medication became the first drug to receive approval from the U.S. Food and Drug Administration (FDA).

In 2016, researchers from the National University of Singapore (NUS) came up with a new method of tablet fabrication, that can make customisable pills that release drugs with any desired release profiles. For instance, you could take the medication once a day and the drug will be slowly released throughout the day at different rates to treat your illness.

Using the system designed by the NUS team, a doctor only needs to draw the desired release profile in a computer software to generate a template for making tablets specific to a patient’s treatment, which can then be used to easily produce the desired pills using a 3D printer. The system is easy to use and does not involve any complex mathematical computation whenever a new release profile is needed.

However, in this area, the possibility of drug abuse and the legal implications have to be addressed.

Medical devices

3D printing is being used for manufacturing medical devices also. It could enable the production of medical equipment in places where there is a shortage, at a fraction of the usual cost and manufacturing time. This is what the Glia project in Gaza is doing, offering open source, low-cost, locally 3D-printed medical supplies.

Through a recent agreement with the Indian state of Andhra Pradesh, a company called think3D is setting up an additive manufacturing center which will offer prototyping and low volume manufacturing to medical device companies in Andhra Pradesh Medtech Zone (AMTZ), looking to tap into the US$5.5 billion Indian medical devices market.

3D models for surgery assistance and training

In addition to the use case from DHA described at the beginning of the article, there are many other instances, where surgeons are relying on 3D printed organs for pre-planning complex surgical procedures. In March 2016, Chinese doctors successfully performed open heart surgery on a nine-month-old baby suffering from a severe heart defect using a 3D printed heart model.

In another type of use for 3D-printed models, physicians at the University of Rochester Medical Center (URMC) developed a way to fabricate artificial organs and human anatomy to create highly realistic simulations for training.

Based on MRI, CT, or ultrasound scans, they created moulds using 3D printing and injected them with a hydrogel. The water consistency of the hydrogel is identical to that found in our bodies giving the artificial organs the same feeling as the real thing.

The designs were tweaked. For example, the concentration of the hydrogel would be altered to add a denser tumor mass to a liver, or a blockage in a kidney, or plaque in an artery. The team can also create bone to simulate procedures involving the spine and skull, creating more rigid structures using the 3D printer. Then the team started assembling entire segments of the body, complete with artificial muscle tissue, skin and fat, and, depending upon the area of interest, the liver, intestines, spleen, kidney, and other adjacent organs and structures. The assembled unit could then be hooked up to a robotic surgical system, and the entire procedure simulated from the first insertion of instruments to completion.

The future

The cost of printers, the ease of using the software, development in materials used for printing, these will all determine the pace and direction of progress in this area. In some areas, the applications are in varying stages of experimentation, while in others, they have already gone mainstream or are on the verge of doing so. However, one thing appears certain. 3D-printing is going to revolutionise medicine in more ways than one.