A tiny titanium nut that had been taken from inside the reactor was just the thing to show that a new technique developed at the Massachusetts Institute of Technology (MIT) can find defects inside materials, even those that have been exposed to radiation, with five times more sensitive than current methods.

The study is predicted to have an impact since it verifies the unexpectedly important role played by the small unseen flaws in the microstructural evolution of materials exposed to irradiation that is confirmed by both experiments and simulations.

The technique that the researchers employed is known as differential scanning calorimetry, and the apparatus they used was essentially the same as the one applied in monitoring energy changes.

The new technology showed that a lot of the damage that occurs inside reactors is at the atomic scale, making it challenging to find using current techniques. Through the way it alters with temperature, the approach offers a way to directly detect this damage.

Because of this, nuclear reactors that are now in use might be able to continue their safe operation for longer periods of time than was previously believed to be possible.

The new method revealed that much of the damage that occurs inside reactors occur at the atomic scale, making it difficult to detect using existing methods. The technique allows for direct measurement of this damage by observing how it changes with temperature.

As a result, it could be used to measure samples from the current fleet of nuclear reactors, potentially allowing for the safe operation of plants far beyond their currently licenced lifetimes.

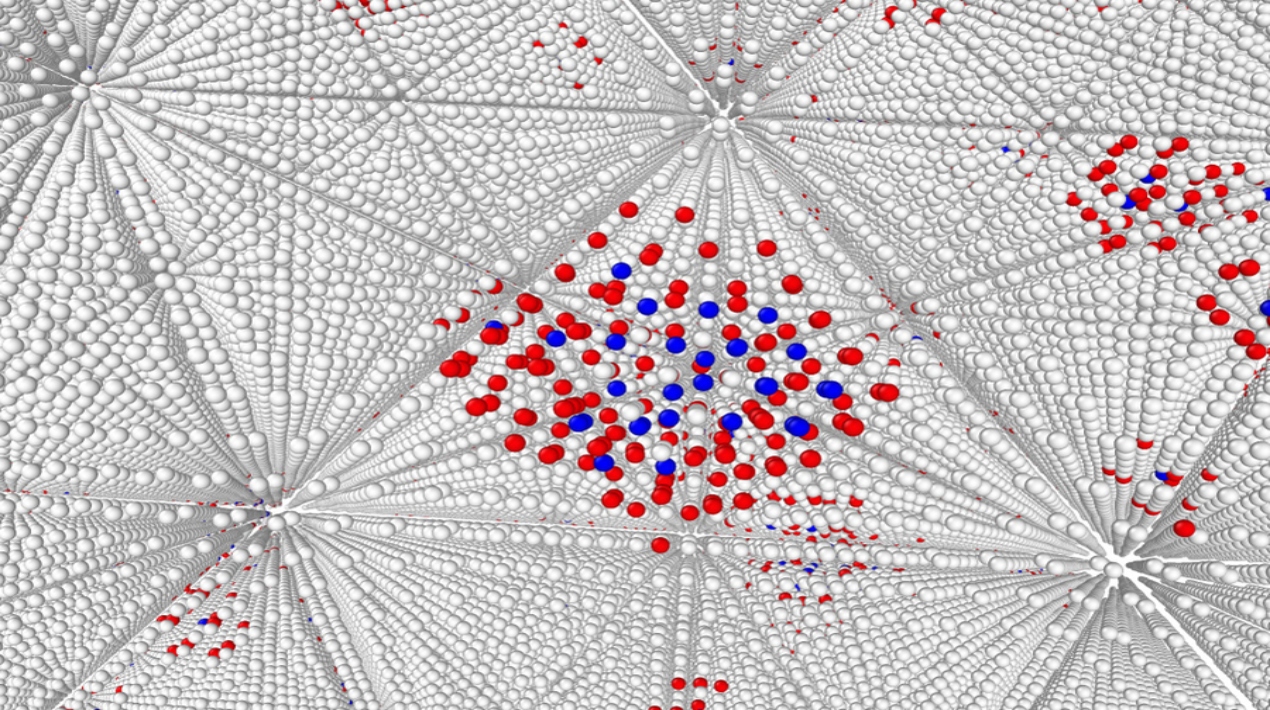

Moreover, the new method looks at the amount of energy stored within a material’s structure rather than directly seeing its physical composition. Any interference with the material’s regular atomic structure, such as that brought on by mechanical stress or radiation exposure, adds extra energy to the substance.

Even if the damage is in the form of atomic-scale flaws that are too small to be seen using microscopes or other detection techniques, it is still possible to compute the total amount of damage within the material by watching and measuring that energy difference.

This method’s underlying theory had been thoroughly developed through calculations and simulations. However, it was the actual testing on that one titanium nut from the MIT nuclear reactor that offered the proof, opening the way for a new method of determining material damage.

In addition, the differential component refers to the fact that two similar chambers are measured at once, one empty and one containing the sample being investigated. The scanning component involves gradually raising the temperature a little at a time and observing how the sample reacts. The difference between the two offers information about the sample’s energy.

The process, according to the researchers, is not limited to the study of metals, nor is it limited to radiation damage. The method could be used to measure other types of defects in materials, such as those caused by stresses or shockwaves, and it could also be applied to ceramics or semiconductors.

They went on to say that measuring defects in other materials can be up to 10,000 times easier than measuring defects in metals and that if they can do it with metals, they can make it extremely, universally applicable.