Computer chips with defects are the misery of the semiconductor industry. Even a seemingly slight defect in a chip containing billions of electrical connections could cause a computer or other sensitive electronic device to fail to perform a crucial job.

Researchers at the National Institute of Standards and Technology (NIST) have devised a method that may concurrently discover specific electrical problems in many microcircuits on the same chip by adapting an existing methodology for identifying errors.

The method may offer a new way to check the interconnected wiring of computer chips in the manufacturing process because it makes use of an Atomic Force Microscope (AFM), a reasonably affordable and widely used imaging tool.

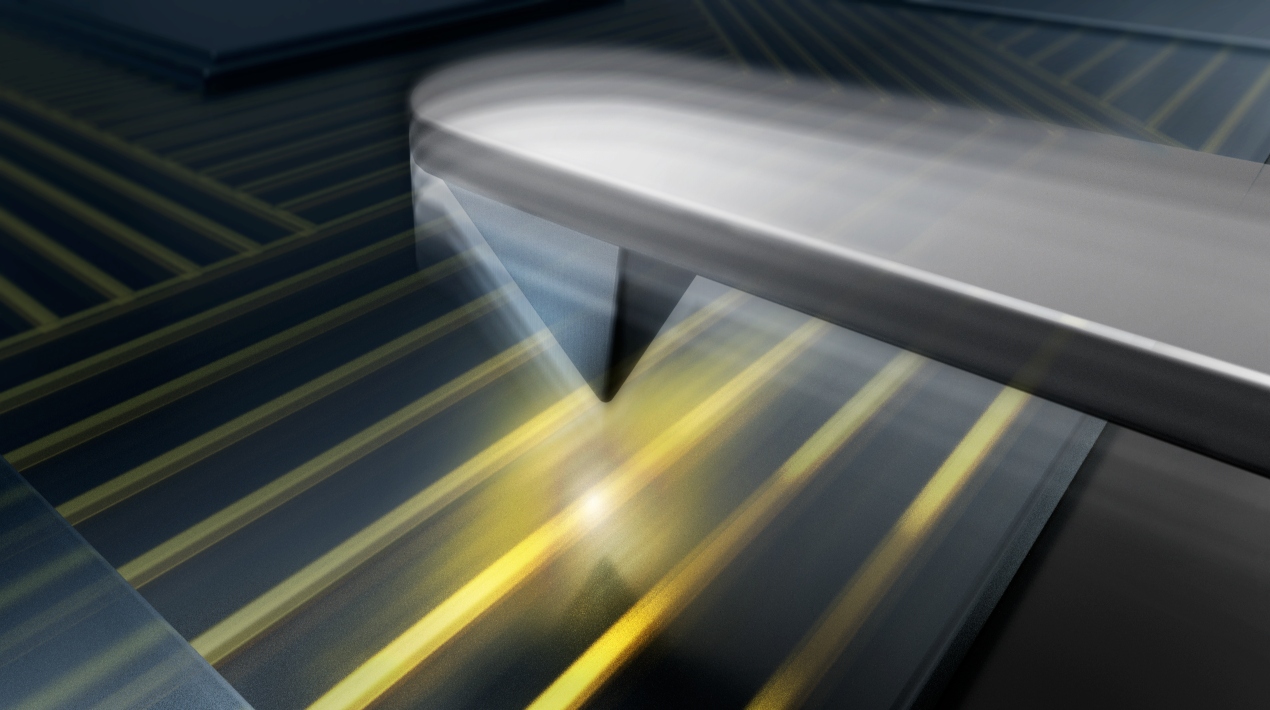

The ultrasharp tip of an AFM is connected to a small cantilever that vibrates like a diving board. In the conventional mode of operation, scientists supply an AC (alternating current) voltage to the probe tip while it scans across parallel wires buried several micrometres (millionths of a metre) beneath the surface of a silicon chip.

The voltage difference between the tip and each wire causes an electric force that manifests as changes in the tip’s frequency or amplitude (height). A wire break or flaw will manifest as a sudden change in the vibration of the tip.

However, the Electrostatic Force Microscopy (EFM) approach of flaw detection with an AFM has a downside. The vibration of the tip is influenced not only by the static electric field of the wire under investigation but also by the voltages of all adjacent wires. These unwanted signals hinder the ability to clearly image flaws in a wire that is being scanned.

NIST researchers solved the problem by delivering AC voltages, supplied by an external generator, to surrounding wires instead of the tip. AC voltage fluctuates between positive and negative values; a graph of the voltage over time resembles a sine wave. In a single cycle, the voltage reaches its highest positive value (the peak) and then its lowest negative value (the valley).

Using this cyclic nature to their advantage, the researchers applied the same AC voltage to surrounding wires as they did to the wire being scanned, with one crucial difference: the voltages to the neighbours were perfectly out of phase. When the voltage to the wire of interest reached its maximum, the voltages to the adjoining wires were at their minimum.

Contrary to the force exerted by the scanned wire, the out-of-phase voltages exerted electrostatic pressures on the AFM tip. These opposing pressures translated to regions of high contrast on an AFM image, making it easier to differentiate the signal from the wire of interest.

The researchers showed their technique by using a test chip with four pairs of wires buried 4 micrometres beneath the surface to obtain clear and accurate photographs of flaws. The researchers also demonstrated that by customising the AC voltages given to each wire to have various frequencies, they could image flaws in many adjacent wires at the same time.

Because the technology relies on an alternating current voltage given remotely to the wires rather than the AFM, the researchers called it remote bias-induced electrostatic force microscopy.

Applying a voltage to the wires instead of the AFM tip may appear to be a minor change, but it makes a significant difference. The method does not necessitate the development of a new instrument and may be simply used by the semiconductor sector. Other approaches for detecting faults, such as X-rays or magnetic fields, are likewise highly precise but require more expensive equipment.