An international interdisciplinary team of scientists [1] that includes Prof Subra Suresh, President of Nanyang

Technological University, Singapore (NTU Singapore), demonstrated

that diamond, the world’s hardest natural material, is also flexible when made

into nanoscale needles. This discovery may lead to new applications in

bioimaging and biosensing, drug delivery, data storage, opto-electronic devices

and ultra-strength nanostructures.

Up to 9% tensile

stretch

The diamond nano-needles – about a thousand times thinner

than a strand of human hair – can be bent and stretched up to nine per cent,

before bouncing back to their original state when pressure is removed. This

is significantly greater than the flexibility of bulk diamond in sizes visible

to the naked eye. The latter is expected to stretch by well below one per cent.

Other strong and brittle materials also usually break when attempts are made to

flex them.

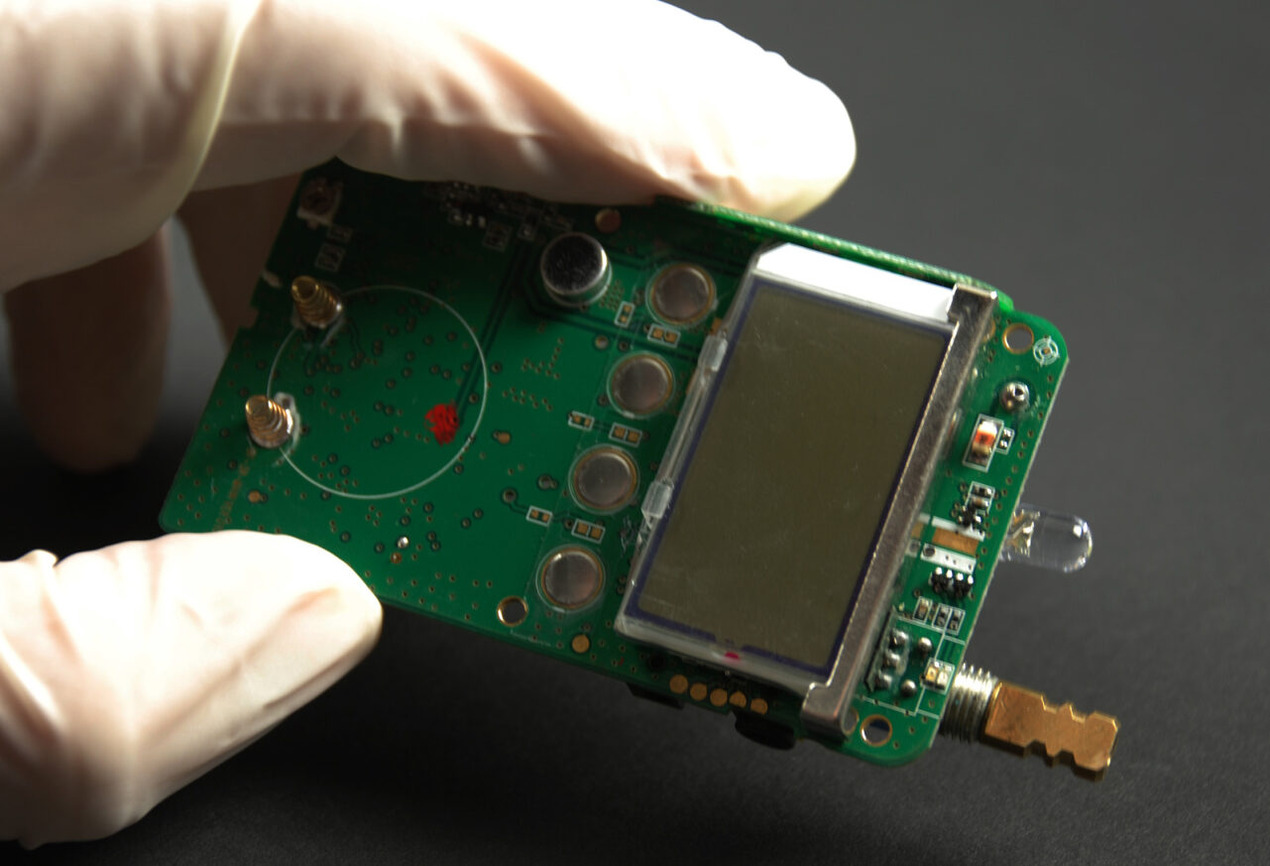

The nano-needles were grown through a special process called

chemical vapour deposition and etched into final shape. The team used a diamond

probe to put pressure on the sides of the diamond nano-needles, recording the process

in real time using a scanning electron microscope. The researchers measured how

much each needle could bend before it fractured.

“Our results were so surprising that we had to run the

experiments again under different conditions just to confirm them,” said Prof

Suresh.

Prof Suresh explained that this this is a demonstration that

what is usually not possible at the macroscopic and microscopic scales can

occur at the nano-scale, where the entire specimen consists of only dozens or

hundreds of atoms, and where the surface to volume ratio is large.”

The team ran hundreds of detailed computer simulations

alongside their experimental tests to understand and explain how the diamond

needles underwent large elastic strains. They learnt after two years of

iterations between simulations and real-time experiments that the deformed

shape of a bent nano-needle is the key in determining its maximum tensile

strain achieved. The controlled bending deformation also enables precise

control and on-the-fly alterations of the maximum strain in the nano-needle,

below its fracture limit.

In addition to showing up to 9% tensile stretch in

single crystal diamonds, Prof Suresh and his collaborators also showed that

polycrystalline diamond nano-needles, where each needle comprises many

nano-size grains or crystals of diamond, can withstand a reversible,

elastic stretch of up to 4% before breaking.

Applications

When elastic strain exceeds one percent, quantum mechanical

calculations in previous theoretical studies indicate significant physical or

chemical property changes. Hence, this demonstrated ability of introducing

elastic strains in diamond by flexing it up to 9% provides opportunities for fine-tuning

its electronic properties. This phenomenon could also be used to tailor

mechanical, thermal, optical, magnetic, electrical, and light-emitting

properties to design advanced materials for various applications.

The nano-diamonds could help design of better ultra-small

biosensors for greater performance.

Another application area of particular significance is the

nitrogen-vacancy (NV) emission centres in diamond. The NV centre consists of a

nearest-neighbor pair of a nitrogen atom, which substitutes for a carbon atom,

and a lattice vacancy. It is one of the point effects in diamond, which are Imperfections

in the crystal lattice of diamond. NV Centres are extremely sensitive to

magnetic fields, temperatures, ion concentrations and spin densities. Since

changes in elastic strains are sensitive to magnetic fields, potential

applications could include such fields as data storage where lasers could

encode data into diamonds.

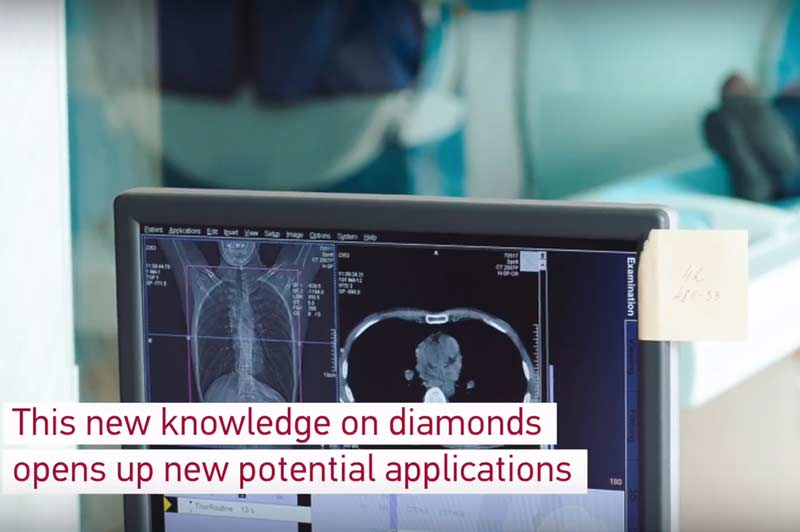

In biosensing applications, NV could also be used in

Magnetic Resonance Imaging (MRI) or Nuclear Magnetic Resonance (NMR) to achieve

even higher accuracy and resolutions, as well as 3-dimensional imaging for

complex nanostructures and biomolecules.

As diamonds are biocompatible, they could also be useful for

drug delivery into cells where strong yet flexible nano-needles are

needed.

This discovery also shows new pathways for producing novel

diamond architectures for mechanical applications, as well as a variety of

functional applications in devices, biomedicine, imaging, micro-testing, and

materials science and engineering.

[1] The findings

were published on 20 April in the journal Science. The interdisciplinary team included

Prof Subra Suresh, President and also Distinguished University Professor at NTU

Singapore, as senior author. Other corresponding authors include Prof Yang Lu

and Prof Wenjun Zhang from the City University of Hong Kong, Dr Ming Dao from

the Massachusetts Institute of Technology (MIT) in United States, with other co-authors

from Hong Kong, United States and South Korea.

In addition to Drs. Subra Suresh, Yang Lu, Weijun Zhang and

Ming Dao, the list of authors includes: Amit Banerjee (lead author), Hongti

Zhang (co-lead author), Muk-Fung Yuen, Jianbin Liu, and Jian Lu from the City

University of Hong Kong; Daniel Bernoulli (co-lead author) from MIT; Jichen

Dong from the Institute for Basic Science, Ulsan, Korea; and Feng Ding from the

Ulsan Institute of Science and Technology, Korea.