A research agreement between Flinders University and a German and Taiwanese backed start-up may lead to the manufacturing and construction of a novel, flat-pack electric vehicle in Australia, using local components and ingenuity.

As reported, the University will be bringing its Research and Development support in this collaboration with the company, in order for the company to reach its goal of boosting Australian content in the design and manufacturing of the company’s recently launched small, modern electric van in the country.

The Partnership

The Director of the University’s Australian Industrial Transformation Institute explained that the Memorandum of Understanding (MOU) seeks to harness Flinders’ R&D expertise in support of the manufacture of this EV under licence here in Australia.

It represents an important step in the potential revival of the Australian automotive industry.

Currently, the van’s components are sourced from multiple places. However, the assembly can occur in destination markets provided the necessary manufacturing skills base is present.

In Australia’s case, this is a phoenix prospect.

This means that a new era of automotive technology could rise from the ashes of the former industry and re-establish a fresh generation of evolved electric vehicles in the country.

University’s R&D Contribution

- Manufacturing Innovation Hub is ideally placed for R&D support to develop advanced manufacturing assembly processes, like collaborative robots.

- The University will bring its research expertise to a range of potential applications.

- This includes 3D manufacturing of components and development of futuristic composite materials as well as on-board vehicle systems and advanced Industry 4.0 manufacturing assembly processes.

- They also have expertise in autonomous vehicles and that could potentially be another aspect of future development.

- This collaboration is laying the groundwork to get Australia back into the automotive manufacturing value chain.

- This represents an important workforce development opportunity. Because the cars are flat pack, they cannot be assembled at home.

- A skilled workforce will be needed, and the aim is for that to be in South Australia.

- Assembly generates one tranche of jobs.

- This will provide increasing opportunities for Australian companies to be suppliers by building supply chains, that can support the development of existing and future vehicle models creates further jobs and that is the goal.

- It is exciting to think that a former home of vehicle manufacturing at Tonsley could once again play a role in the re-emergence of vehicle manufacturing through the expertise of the University in advanced manufacturing and its Research and Development support for “Australianising” the vehicle.

The Electric Van (Australia Smart Pack EV)

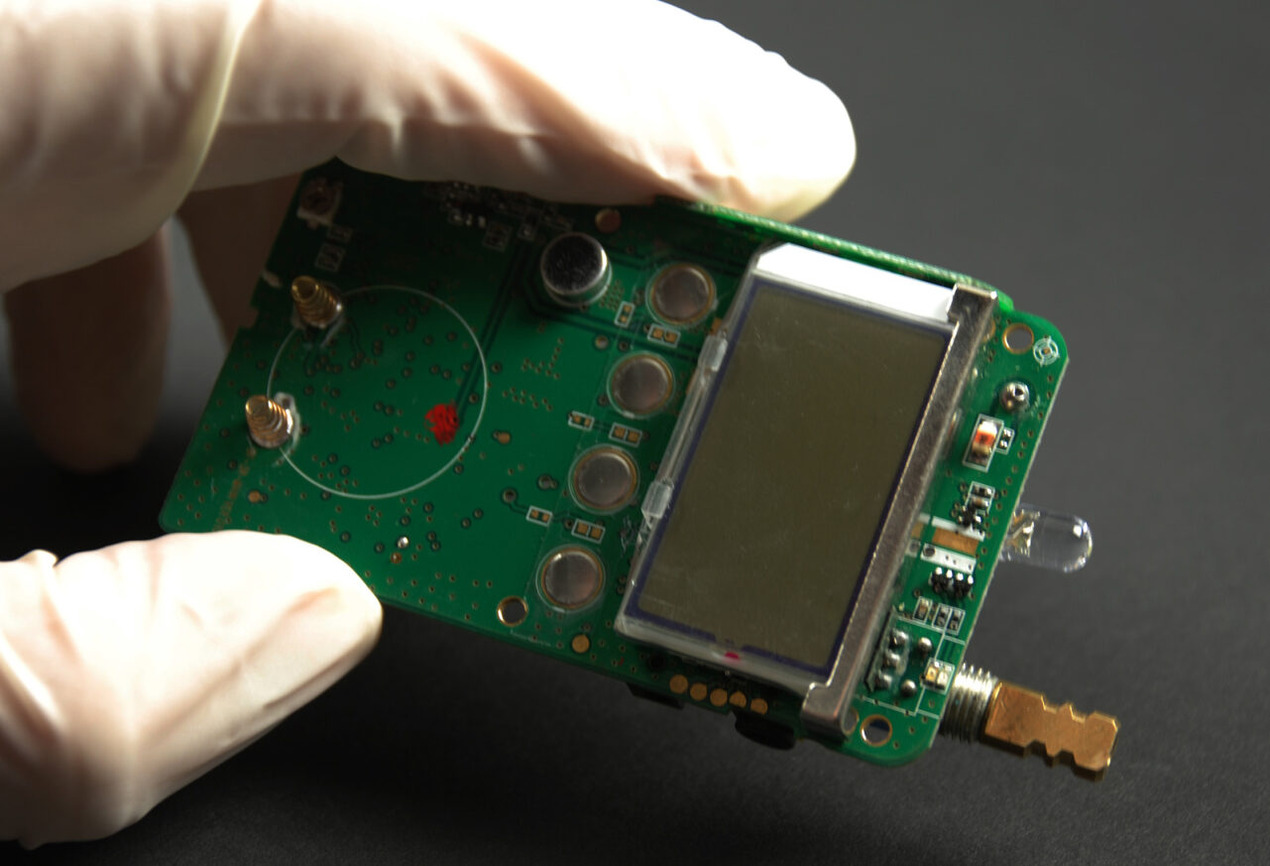

- The van is made of composite materials. Thus, it is lightweight and efficient. It is essentially stuck together with space-age adhesives rather than the traditional nuts, bolts and rivets.

- And being electric, it is energy efficient, especially if recharged with renewables. Fewer moving parts mean less maintenance too.

- Flinders’ Tonsley This ‘business on wheels’ concept will be reliable and efficient for getting workers to a job site.

- Plus, it would also be an excellent solution for transporting materials and tools where they are needed on big scale sites such as mines, especially if Flinders’ research into autonomous technologies were applied.

- In essence, EV advanced manufacturing holds promise for the regeneration of the automotive industry sector as well as efficiencies for business, supported by Flinders’ research know-how.