|

Getting your Trinity Audio player ready...

|

Nestled in the heart of the Yangtze River Delta, a transformation is unfolding within the food industry, reshaping the very essence of food production. In the bustling city of Kunshan, Jiangsu Province, the symphony of technology and tradition plays out in a coffee roasting factory.

Here, a mesmerising dance of countless pipes and machinery forms multi-story production facilities. It’s a captivating sight where green coffee beans embark on an incredible journey, ascending to great heights before gracefully descending through a meticulously choreographed sequence of processes.

This region’s food industry continues to evolve, expanding its value chain, embracing the dual-circulation pattern, and elevating its intelligent manufacturing capabilities. In doing so, it breathes new life into the Yangtze River Delta, infusing it with a fresh wave of developmental vigour.

Not far from Kunshan, in Taicang, Jiangsu, a food production base sets the stage for a fascinating spectacle. Here, more than ten ice cream cones are crafted every second, a testament to the marvels of intelligent manufacturing. The production equipment operates seamlessly, driven by automation and digitalisation, setting new standards for intelligence and environmental responsibility.

But the impact of intelligent manufacturing goes beyond mere efficiency; it’s reshaping the very landscape of the food industry in the Yangtze River Delta. The region’s integration fosters a concentration of food industry enterprises.

Gu Jun, the director of the Economic Development Promotion Bureau of Kunshan Development Zone, attests that in recent years, the world’s leading food manufacturers, specialising in chocolate, ice cream, beverages, and other snack foods, have strategically concentrated their operations in the fertile grounds of the Yangtze River Delta.

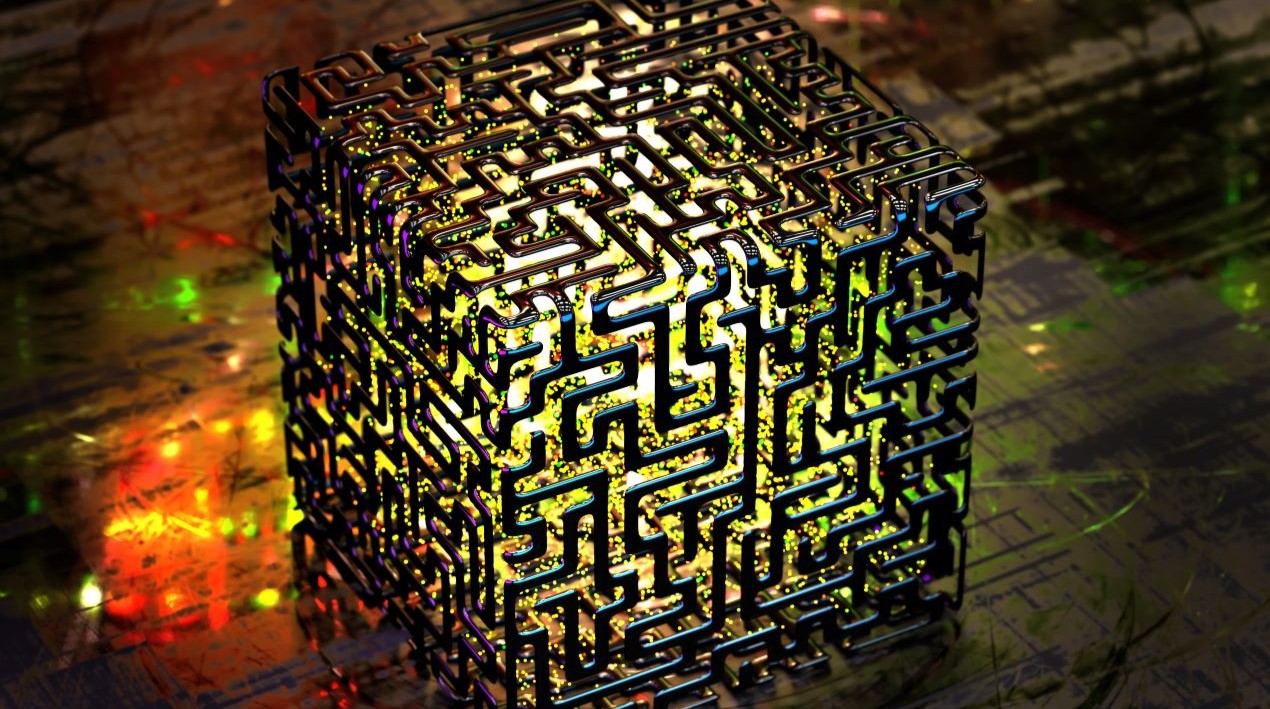

This isn’t merely a random convergence; it’s the result of a technological revolution that has been steadily advancing over recent years. Known as digitalisation, it’s the driving force behind what they call Industry 4.0 or the Fourth Industrial Revolution.

At its heart, digitalisation seamlessly integrates digital technologies and data-driven processes into manufacturing operations, all with the overarching goal of enhancing efficiency, productivity, and flexibility.

In this transformative journey, the primary role of digitalisation is to facilitate data collection and analysis. Digital technologies seamlessly gather vast volumes of data from sensors, machines, and devices that populate the factory floor. This trove of data is then meticulously analysed through advanced analytics and machine learning algorithms. These processes unveil patterns, optimise operations, and predict maintenance needs, ushering in substantial improvements in overall efficiency.

But digitalisation doesn’t merely stop at data collection; it catalyses real-time monitoring and control of manufacturing processes. Through the deployment of sensors and IoT devices, machinery and production processes are under constant surveillance, enabling manufacturers to make instantaneous adjustments to enhance production and maintain product quality. This real-time visibility and control serve as the bedrock of intelligent manufacturing.

Beyond real-time control, digitalisation is the catalyst for smart manufacturing. It leads to the integration of smart technologies, such as automation, robotics, and AI, into manufacturing operations. This infusion equips production lines with greater flexibility and responsiveness, enabling them to swiftly adapt to evolving market demands, thereby elevating the intelligence of manufacturing processes.

The benefits of digitalisation extend to supply chain integration, streamlining communication between manufacturers and suppliers. This translates to more efficient inventory management and rapid responses to fluctuations in demand, which, in turn, reduce lead times and operational costs, benefiting both the economy and the environment.

Manufacturers seeking to offer customisation and personalisation find digitalisation indispensable. Digital tools and technologies streamline the production of customised products, meticulously tailored to meet individual customer requirements, all while ensuring production efficiency remains uncompromised.