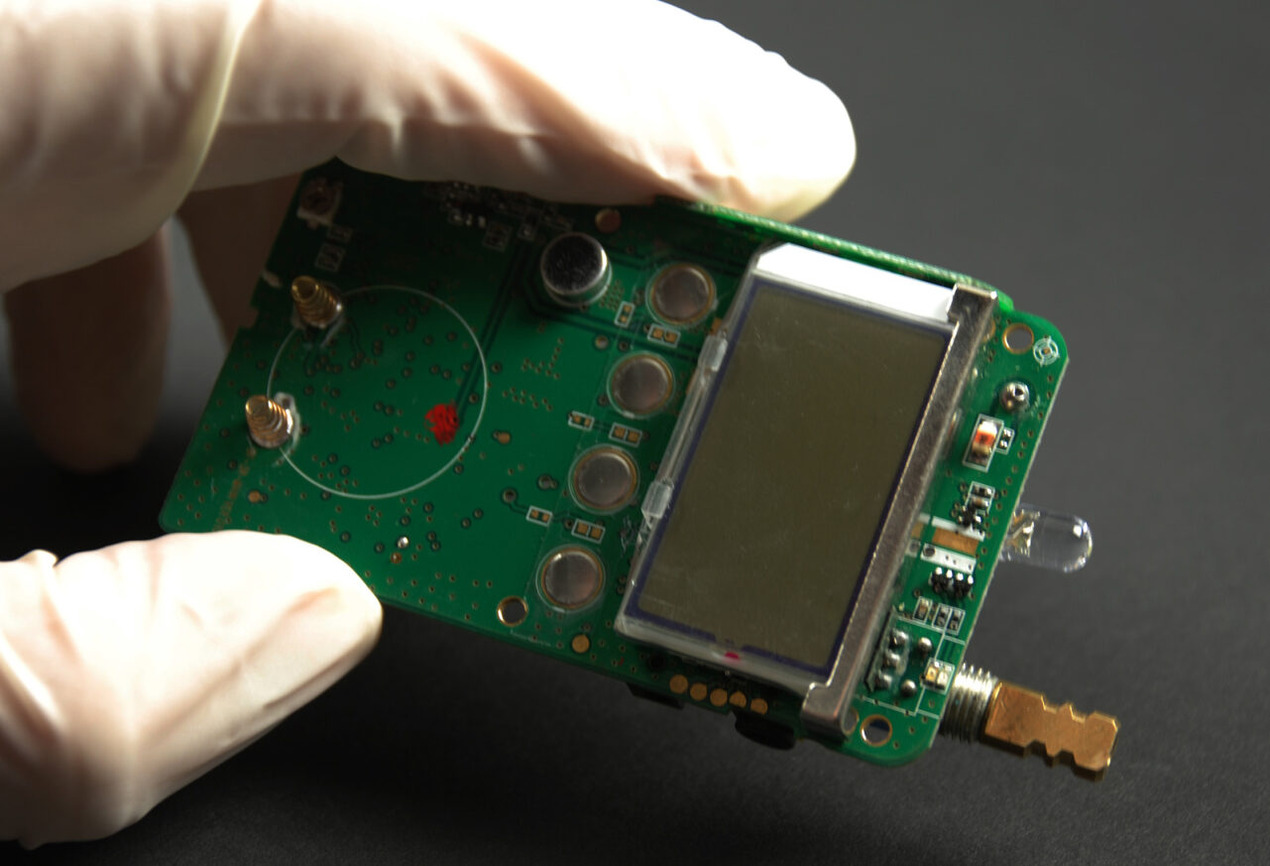

A Swinburne University of Technology project achieved a major milestone when it had successfully 3D printed a replacement lug on an automotive headlamp assembly by using a robot.

According to a recent report, the Repairbot project has the ability to add value to an industry impacted by skills shortages and a lack of newly skilled personnel.

Repairbot Project

The project was made possible through collaboration with an automated systems company, supported by an automotive aftercare company, and backed by the Federal Government via the Innovative Manufacturing Cooperative Research Centre (IMCRC).

Dr Mostafa Nikzad, the University’s materials scientist, developed the in-house formulated polypropylene composite material used in the process.

They had to create a material with the right characteristics for 3D printing polypropylene, with the strength and toughness required to meet automotive quality standards, to ensure the compatibility with automotive grade injection moulded plastic.

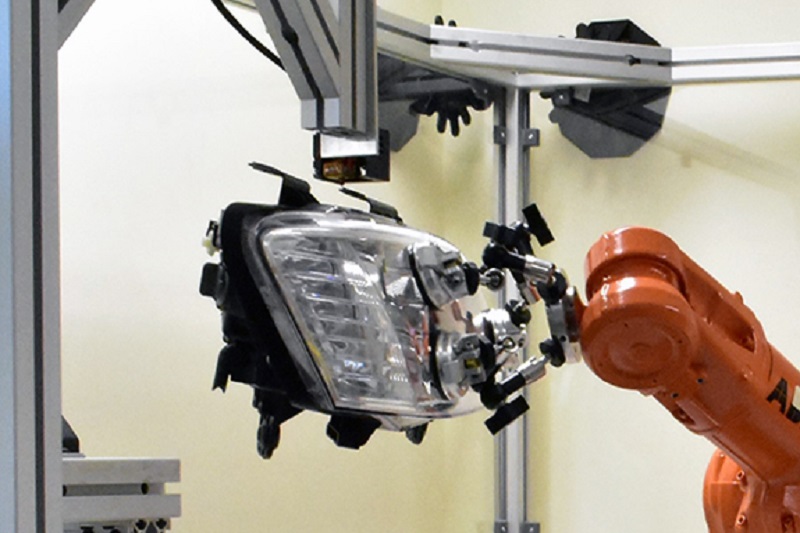

The University’s Dr Mats Isaksson led the robotics team that used the new material to engineer the 3D print of a replacement lug directly on headlight housing.

By using a robotic arm to precisely manipulate the headlight under a stationary 3D print head, complex geometries can be printed without the need for support material.

Fast-tracking on-the-job training

The application opens the door to a new way of developing skills in the automotive repair industry as technicians are able to work alongside robotics systems to fast-track their on-the-job training.

The automated systems company founder shared his amazing experience of witnessing something he had envisioned turn to reality within 3 years.

The Repairbot will allow repairs to be conducted on damaged automotive plastic parts not currently repairable by technicians.

This is a major step towards fulfilling the project goal of a complete prototype for automatic repairs of headlight assemblies.

The success of the project should be credited to the close collaboration between roboticists and material scientists.

The truly cross-disciplinary nature of this project has made it possible to develop new materials and methodologies hand-in-hand with the novel robotic solutions.

Example of industry and research collaboration

The CEO and Managing Director of IMCRC congratulated the Repairbot team on reaching this significant project milestone.

He said that the Repairbot project is a great example of industry and research collaboration.

The University’s researchers have wholeheartedly embraced their industry partner’s idea of developing a technology-driven solution that will automate the repair service for automotive plastic parts.

This milestone was reached because of their commitment to push materials and technology boundaries to help solve an industry specific problem that has the potential to transform the whole automotive repair industry.

IMCRC as a collaborative partner is proud to help catalyse these transformative outcomes.

Road Ahead

The project, according to the automotive aftercare company, is still 18 months away from hitting the shop floor.

It is currently moving into the next stage of validation testing of the material in application and fine-tuning the digital development of the software to manage design and repair procedures.

Repairbot has drawn interest from all pockets of the repair industry and other industries including defence.

Early talks are under way with a range of potential users of the system including OEMs, repair facilities and parts suppliers.