Faster-charging and more sustainable batteries with a life up to three times greater than lithium ion are being built with technology developed at The University of Queensland.

A Brisbane-based graphene manufacturing firm which recently listed on the TSX Venture Exchange in Canada will manufacture battery prototypes for watches, phones, laptops, electric vehicles and grid storage under a research agreement with scientists from UQ’s Australian Institute for Bioengineering and Nanotechnology (AIBN).

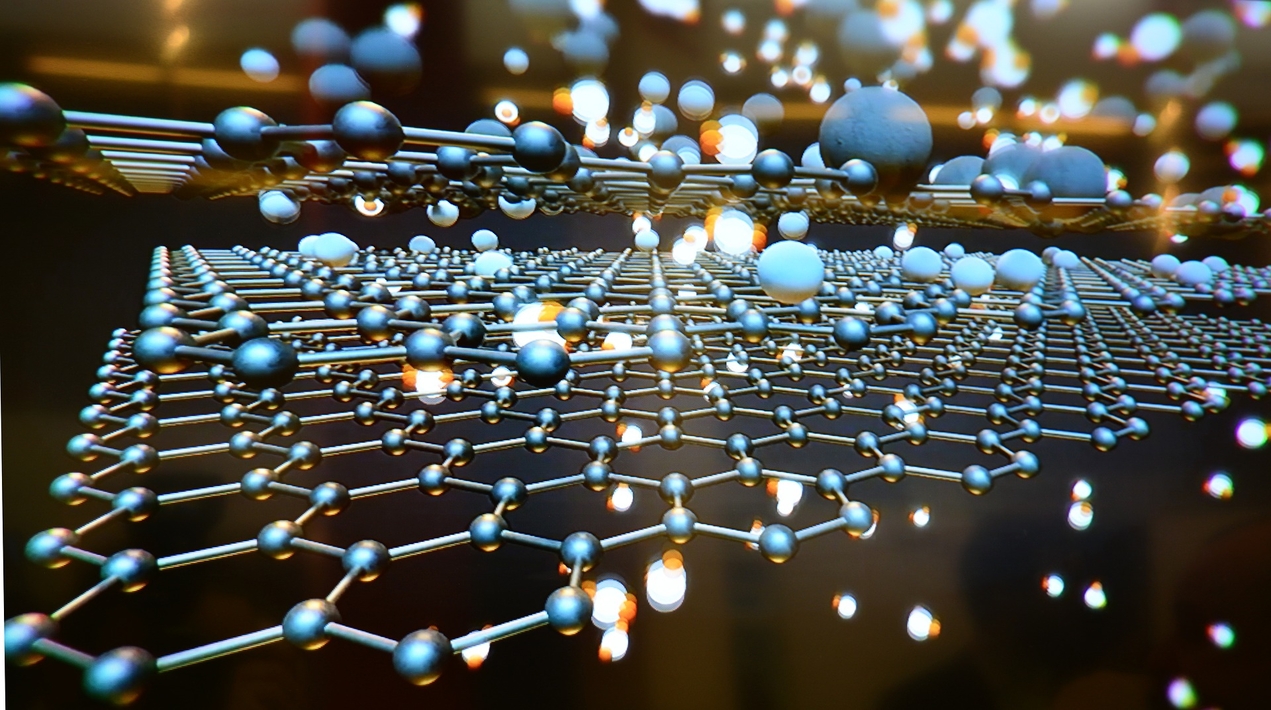

Professor Michael Yu, Dr Xiaodan Huang and postdoctoral student Yueqi Kong devised technology to make graphene into more efficient electrodes for powering batteries, which has been patented and licensed by UQ commercialisation company, UniQuest.

AIBN Director Professor Alan Rowan said UQ was delighted to partner with GMG to translate scientific ideas into commercial solutions through the development of more efficient and greener batteries.

Professor Rowan stated that after several years of dedicated research into improving the aluminium ion battery, the team is excited to be at the phase of developing commercial prototypes for more sustainable, faster-charging batteries.

Testing showed rechargeable graphene aluminium ion batteries had a battery life of up to three times that of current leading lithium-ion batteries, and higher power density meant they charged up to 70 times faster. The batteries are rechargeable for a larger number of cycles without deteriorating performance and are easier to recycle, reducing the potential for harmful metals to leak into the environment.

The UniQuest CEO said that the aluminium ion battery with graphene electrodes could transform the existing rechargeable battery market, dominated by lithium ion.

Lithium-ion batteries demand the extraction of rare earth materials using large amounts of water and are processed with chemicals that can potentially harm the environment. This project has real potential to provide the market with a more environmentally friendly and efficient alternative, he said.

The Head Scientist of the graphene manufacturer stated that the project could deliver far-reaching benefits for energy storage, while the batteries were also safer because they do not use lithium, which had been known to cause fires in some mobile phones.

“This project is a great example of academia and business working together,” he said.

The current recyclability of batteries is highly problematic due to their chemical properties and the stockpiling of dead batteries presents a large and looming environmental and public safety concern.

The CEO of the graphene manufacturer said to use local raw materials to manufacture battery cells at a competitive cost to replace imported lithium-ion cells is a massive opportunity for the company and Australia to reduce supply chain risks and create local jobs.

“We’re excited about developing the commercial prototypes followed by initial production here in Australia – at a location yet to be determined,” he said.

UQ’s research team was awarded $390,000 over three years to develop the graphene aluminium ion technology from the Australian Research Council’s Linkage Project in 2020.

The Graphene industry is entering a new phase, a phase of growth. The industry has accumulated significant experience over the past 10-12 years to bring about this phase.

Research from 2019 offers opinions about the recent past and future outlook of the graphene industry based on the report ‘Graphene, 2D Materials and Carbon Nanotubes: Markets, Technologies and Opportunities 2019-2029’.

The industry spent years to arrive at a set of applications in which graphene immediately makes commercial sense. In the early years, the industry was in a divergent exploratory phase in which players pursued numerous opportunities across diverse and often unrelated markets. The market is now at a more convergent and focused phase during which a realistic application pipeline is established.