The region’s Transport and Main Roads Minister stated that the first Queensland Rail trains to be fitted with new European Train Control System (ETCS) technology had arrived at a specialised facility in Redbank. The project is expected to support up to 30 jobs once work ramps up on the contract later this year. The Minister noted that delivering better rail services for commuters and investing in rail to support more jobs and skills development is part of Queensland’s COVID-19 Economic Recovery Plan.

The Queensland Government has backed a $1 billion pipeline of rail manufacturing work to support Queensland communities, including building trains in Maryborough for Cross River Rail, and is also investing $635 million in ETCS technology to make the local rail network work smarter and build future capacity for more services.

Fitting out the first two trains with ETCS technology marks a significant milestone for Cross River Rail and south-east Queensland’s public transport network. The new world-class signalling system enables increased capacity on the rail network. This means services are more reliable, safer and allows the wider rail network to run more efficiently.

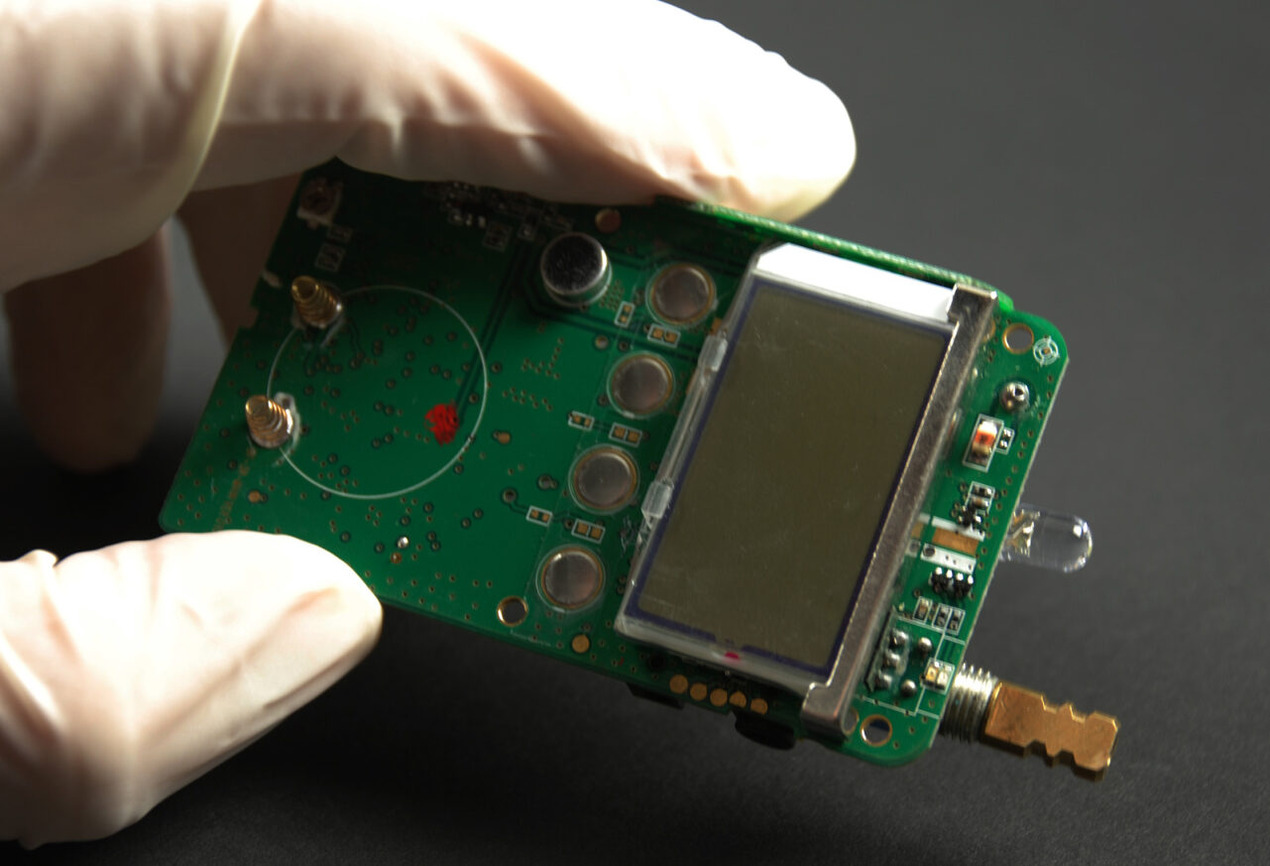

The train fit-outs at Redbank involve the installation of new technology to the trains, including axle sensors that detect the train’s speed and two new touchscreens added to the drivers’ cabin. Signalling equipment is also being installed on the Shorncliffe line, so the new technology can be tested on trains when they’re not in service.

When they’re up and running, the trains will essentially be in constant communication with Queensland Rail’s Rail Management Centre via a radio system, trackside technology and onboard equipment, allowing the train’s exact position, direction and speed to be known at all times. This means trains can travel closer together more safely and train schedules can be updated automatically, giving commuters more accurate and timely information.

The Member for Bundamba stated that workers at Redbank would upgrade 64 Queensland Rail trains over the next two years, and by the end of the year, four trains could be upgraded at once. He noted that delivering stable and secure manufacturing jobs is a key part of Queensland’s COVID-19 economic recovery plan. There are currently 12 workers fitting out the trains on-site, with up to 30 planned by the end of the year.

All up, about 200 workers across south-east Queensland are bringing ETCS technology to the local rail network, while the new technology will support new and ongoing technical jobs at Queensland Rail, he added. The world-class technology is another example of the benefits Cross River Rail will not only create when it opens but is delivering for Queensland’s economy right now, when it’s needed the most.

ETCS is used on rail networks around the world, including in France, the UK, Saudi Arabia, India and China. It will be operational in southeast Queensland ahead of Cross River Rail’s opening in 2025.

ETCS fast facts:

- The European Train Control System (ETCS) will increase in safety, capacity, efficiency and reliability for the inner-city rail network

- The ETCS project involves delivery and integration of new trackside equipment, data radio systems and a rail traffic management system, as well as onboard train equipment

- ETCS is necessary for the safe operation of Cross River Rail’s twin tunnels but will benefit the wider rail network

- Two trains are at Redbank to be fitted out with ETCS technology

- By the end of the year, four trains at a time can be upgraded using the four railroads available at the facility

- 64 trains will be upgraded with ETCS equipment over the next two years

- Once testing of the first train is complete at Redbank in the coming months, testing using non-revenue trains will start on the Shorncliffe line by the end of the year

- Queensland Rail, the Cross River Rail Delivery Authority and an industry partner are working together closely to deliver ETCS.