Scientists and engineers are constantly creating new materials with unique properties that can be used for 3D printing but figuring out how to print with these materials can be a difficult and expensive problem. Often, an expert operator must use manual trial-and-error to determine ideal parameters that consistently print a new material effectively over thousands of prints. These parameters include printing speed and the amount of material deposited by the printer.

Hence, the Massachusetts Institute of Technology (MIT) has now used artificial intelligence (AI) to speed up this process. They created a machine-learning system that uses computer vision to monitor the manufacturing process and correct errors in how the material is handled in real-time.

The project is the first demonstration of building a manufacturing system that uses machine learning to learn a complex control policy, according to senior author Wojciech Matusik, professor of electrical engineering and computer science at MIT.

They applied the controller to a real 3D printer after using simulations to teach a neural network how to change the printing parameters to reduce error. Compared to all other 3D printing controllers, their system produced objects more accurately.

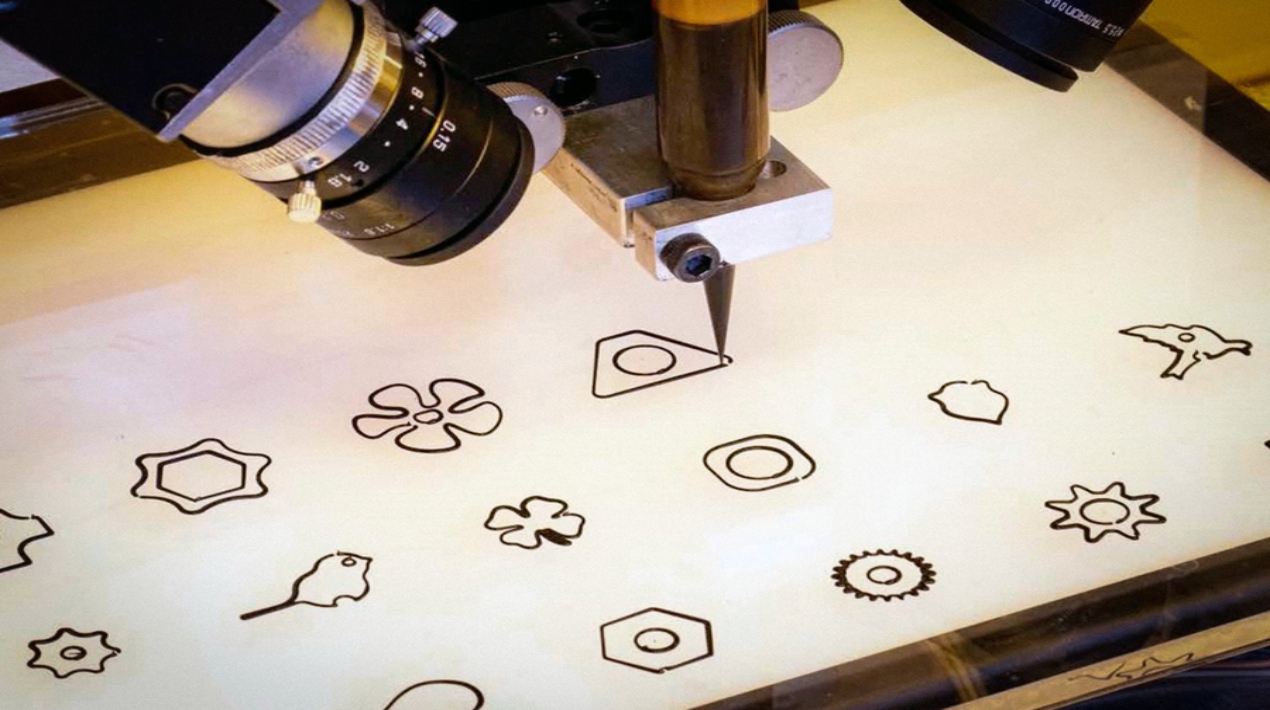

The researchers created a machine-vision system using two cameras pointed at the nozzle of the 3D printer to measure what was happening on the printer in real-time. The system illuminates the material as it is deposited and determines the thickness of the material based on how much light passes through.

Once the controller has processed the images it has received from the vision system, it will change the printer’s direction and feed rate in response to any errors it finds.

However, creating millions of prints to train a neural network-based controller to comprehend this manufacturing process is data-intensive. So instead, the researchers created a simulator.

They employed a technique called reinforcement learning to train their controller, which teaches a model by rewarding it when it makes a mistake. The model was tasked with choosing printing settings that would produce a specific object in a virtual setting. The model was awarded when the parameters it selected minimised the error between its print and the anticipated result after being given the predicted result.

An “error” in this context means that the model either dispensed too much material, filling in spaces that should have remained empty, or not enough material, leaving spaces that needed to be filled in. The model improved its control policy to maximise the reward as it ran more simulated prints, increasing its accuracy.

Conditions typically alter because of minute fluctuations or printing process noise. So, the researchers developed a numerical model that roughly represents 3D printer noise. They utilised this approach to simulate noise, which produced more accurate outcomes.

The controller produced items more accurately than any other approach examined. It excelled at infill printing or printing an object’s interior. Other controllers deposited so much material that the printed item bulged, but the researchers’ controller altered the printing direction. The control policy may learn how materials spread and change parameters.

Researchers intend to develop controllers for various production processes using this 3D printing approach. They want to know how to modify the approach for printing numerous layers or materials at once. Their method was based on the idea that each material has a fixed viscosity, or “syrupiness.” However, a future version could use AI to recognise and change viscosity in real-time.