The Australian National University (ANU) is hosting a new training centre aimed at upskilling the next generation of researchers in cutting-edge 3D imaging and analysis technology to help repair bones, safely store CO2, deactivate viruses on surfaces and recycle car parts among a range of critical applications.

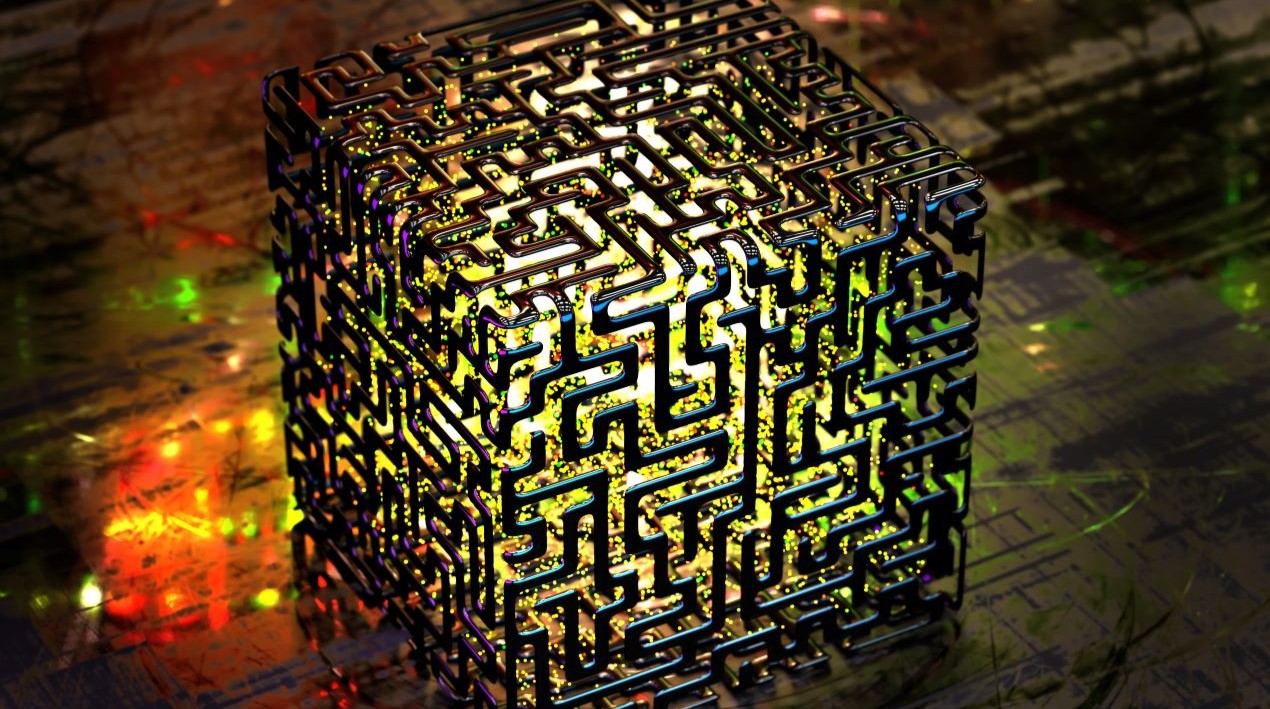

The ARC Training Centre for Multiscale 3D Imaging, Modelling and Manufacturing, M3D Innovation, is using a “disruptive” digital imaging, analysis, modelling and manufacturing technology developed at ANU for more than 15 years.

The micro-imaging technology provides users with 3D “supervision” into a range of materials at scales ranging from metres to 10 nanometres – a measurement 1,000 times smaller than the width of a human hair.

The technology was originally developed by a team of researchers with M3D Innovation Director, Professor Mark Knackstedt, who has won a Eureka Prize as well as an ENI award – the ‘Nobel prize’ for energy resources research – for his innovation.

He noted that the aim is to gather researchers from ANU and Queensland University of Technology, 15 industry partners and end users to harness the ‘super-power’ of advanced imaging and analysis technologies. He added that a vibrant research training environment is being built and a workforce that is expert in applying the new technology to a range of new industry sectors is being created. Moreover, PhD students and early career researchers in industrial collaboration and commercialisation are being mentored.

Already, incredible strides have been made through a range of exciting projects. This includes using the technology to investigate green steel production via hydrogen-based processes; safely storing CO2 in aquifers to fight climate change, recycling car parts for a circular economy, regenerating bones with biodegradable scaffolds and designing custom bone implants.

Partners at QUT have developed new technology during the COVID-19 pandemic, using etching techniques to roughen surfaces to deactivate bacteria and viruses. This is a technique that could be used to deactivate COVID-19 on metal surfaces in hospitals and clinical settings.

M3D Innovation is funded by the Australian Government under the Australian Research Council Industrial Transformation Training Centres scheme. Professor Knackstedt said they are grateful for the Australian Government’s investment and support for this important field of science and for the translation to industry partners.

ANU and Australia are world leaders in this space. Their work at M3D Innovation will boost the country’s capacity and deliver new graduates and researchers with critical skills and knowledge across novel manufacturing, modelling and imaging.

The global 3D imaging market size was valued at US$25.7 billion in 2021 and is expected to grow at a compound annual growth rate (CAGR) of 18.2% from 2022 to 2030. 3D imaging is the procedure of rendering a three-dimensional image to create the optical illusion of depth.

During the 3D imaging process, two or more motion cameras are employed to capture a three-dimensional object for these 3D images to be produced. High-resolution images are created by combining 3D image sensors, cameras, and screens. As a result, 3D imaging is widely used in hospitals, the entertainment industry, architecture, construction, and automotive.

While the COVID-19 pandemic negatively impacted market growth, ongoing technological developments in the field of 3D imaging and the widespread adoption of and need for 3D imaging systems in different sectors are expected to drive the market in the coming future.

The growing prevalence of chronic diseases worldwide coupled with increased awareness of the benefits of 3D imaging technology are also factors contributing to the growth in demand for 3D imaging solutions.