Researchers have developed a new approach to fitting the 2D material in the silicon wafers as next-generation microchip materials. The 2D materials, at the nanoscale scale, transport electrons significantly more efficiently than silicon. The fragile, two-dimensional, as thin as a single atom sheet of flawless crystals could be the silicon next-generation transistor materials’ heirs.

From time to time, researchers are seeking alternative materials to help expedite microchip development because silicon material for the microchip will soon reach its plateau. According to Moore’s Law, devices manufactured from silicon will lose their electrical qualities after they reach a particular size. And since the 1960s the number of transistors on a microchip has multiplied yearly, developers must plan for the plateau.

However, significant barriers must be overcome before the electronics industry can migrate to 2D materials. The scientists must determine how to construct the materials on industry-standard silicon wafers while maintaining their precise crystalline shape. MIT engineers researched to identify solutions.

“There has been no technology to create 2D materials in a single-crystalline form on silicon wafers until now. Therefore the entire community has battled to accomplish next-generation CPUs without transferring 2D materials,” Kim added. “We have now completely surmounted this challenge with the ability to fabricate circuitry as small as a few nanometers. This will alter the paradigm of Moore’s Law.”

MIT Co-authors include Ki Seok Kim, Doyoon Lee, Celesta Chang, Seunghwan Seo, Hyunseok Kim, Jiho Shin, Sangho Lee, Jun Min Suh, and Bo-In Park, as well as colleagues from the University of Texas at Dallas, the University of California at Riverside, Washington University in Saint Louis, and institutions throughout South Korea.

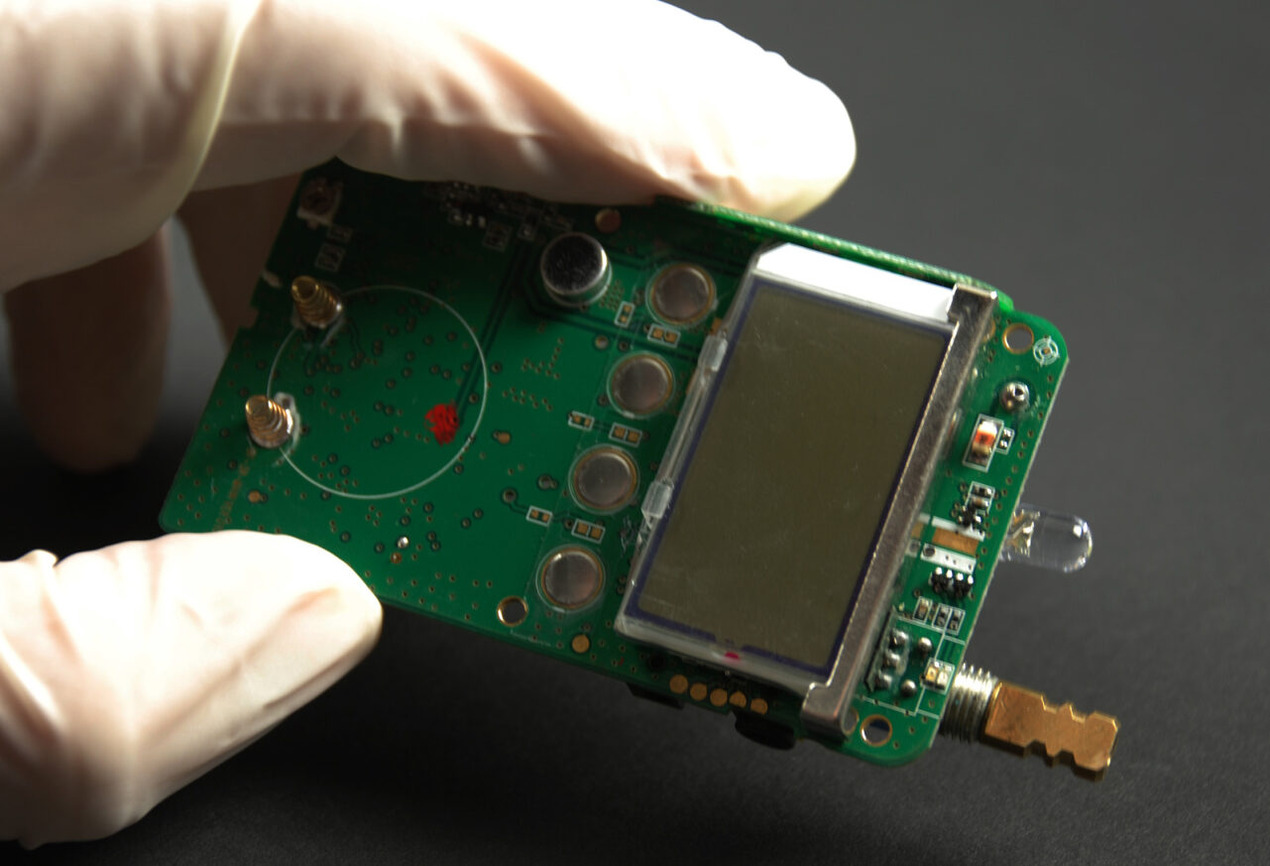

The researchers devised a method for chip producers to fabricate ever-smaller transistors from 2D materials by growing them on existing silicon and other material wafers. The team employed “nonepitaxial, single-crystalline growth” for the first time to build pure, defect-free 2D materials onto industrial silicon wafers. They used this technology to create a simple, functional transistor out of transition-metal dichalcogenides, or TMDs, which are known to conduct electricity better than silicon at nanoscale scales.

“We anticipate that our approach will allow the construction of 2D semiconductor-based, high-performance, next-generation electronic devices,” says Jeehwan Kim, an associate professor of mechanical engineering at MIT. “Using 2D materials, we’ve discovered a means to catch up to Moore’s Law.”

To create a 2D material, researchers have traditionally used a laborious procedure in which an atom-thin flake is meticulously exfoliated from bulk material, like peeling an onion’s layers. However, the team’s unique “nonepitaxial, single-crystalline development” method eliminates the need for peeling and looking for flakes of 2D material.

The researchers instead employ traditional vapour deposition methods to push atoms over a silicon chip. The atoms eventually settle on the wafer and nucleate, resulting in the formation of two-dimensional crystal orientations. Each “nucleus,” or seed of a crystal, would develop in random orientations across the silicon wafer if left alone. However, Kim and his colleagues discovered a mechanism to align each emerging crystal, resulting in single-crystalline zones over the entire wafer.

To accomplish this, scientists first covered a silicon wafer with a “mask” – a silicon dioxide layer that they structured into tiny pockets, each designed to trap a crystal seed. They then pumped a gas of atoms across the masked wafer, settling into each pocket to produce a 2D material – in this case, a TMD.

The masks’ pockets trapped the atoms and encouraged them to assemble in the same single-crystalline orientation on the silicon wafer. The findings are startling since they discovered single-crystalline growth everywhere, even when there is no epitaxial relationship between the 2D material and the silicon wafer. The team used their masking method to create a primary TMD transistor with the same electrical performance as a pure flake of the same material. According to Kim, in the future, numerous 2D materials might be developed and stacked together in this manner to create ultrathin, flexible, and multifunctional films.