The Innovation and Technology Commission’s (ITC) Re-industrialisation Funding Scheme (RFS) has approved an HK$15 million project by a Hong Kong based restaurant. The project aims to set up a new smart production line for mooncake products and is intended to support the food manufacturing and processing industry in Hong Kong.

The restaurant is a member of a popular food and beverage company that was established in Hong Kong in 1956. The funding is expected to facilitate the company’s transition to smart production lines.

According to the Commissioner for Innovation and Technology, Hong Kong’s food products have an excellent reputation globally for maintaining high standards of food safety and quality. The Innovation and Technology Commission (ITC) is encouraging the food manufacturing industry in Hong Kong to capitalise on its competitive advantages. With the support of the RFS, new smart production lines can be established in Hong Kong to increase production capacity and expand into new markets. This funding is expected to strengthen the “Made in Hong Kong” brand.

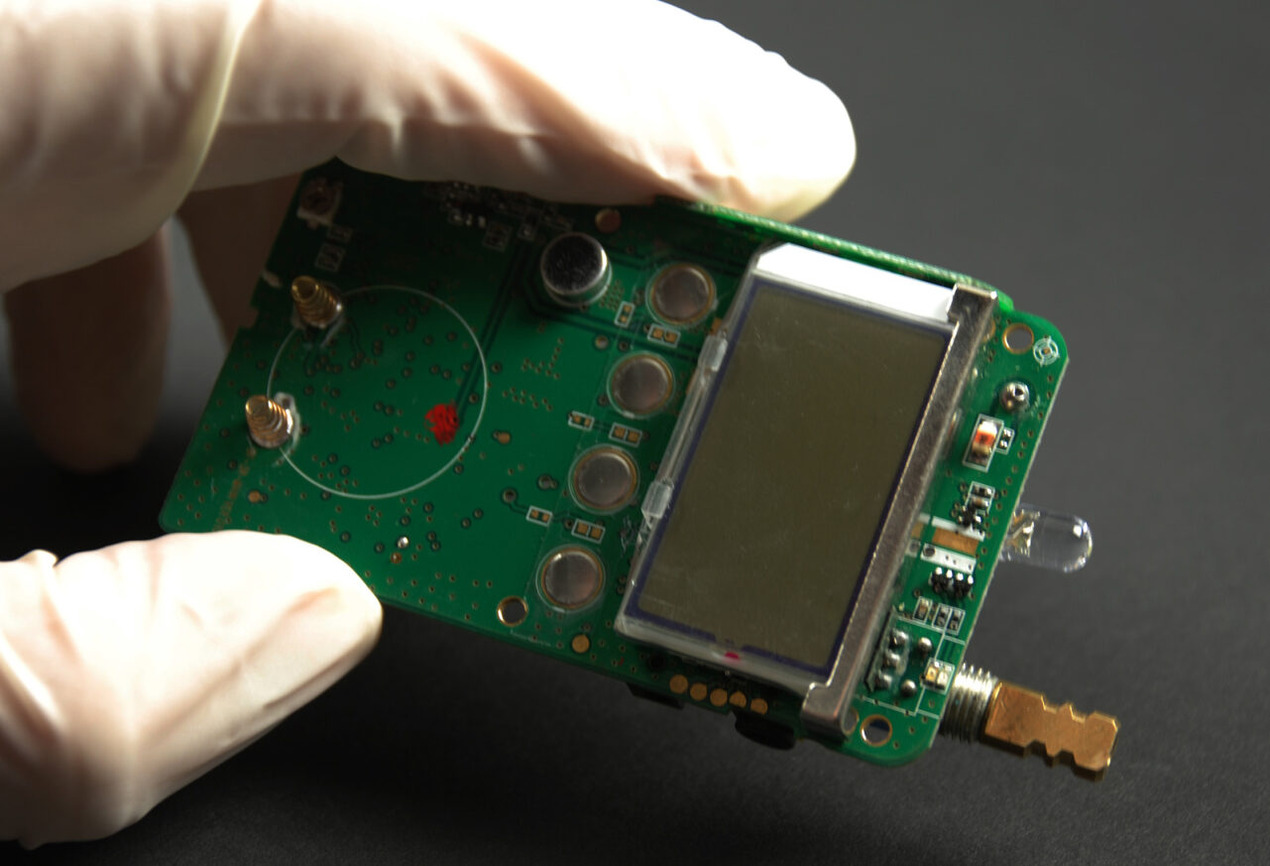

The project has a total cost of around HK$49 million, with the manufacturer contributing approximately HK$34 million. The production of the new smart production line for mooncake products will take place in Tai Po InnoPark, using cutting-edge technologies such as the Internet of Things, automation, robotics, machine vision, advanced human-machine interfaces, and digital manufacturing systems. These technologies will enable the establishment of a real-time data-driven smart production line. The products produced will be primarily sold in the local market, but they will also be exported to other markets.

The Re-industrialisation Funding Scheme (RFS) is structured such that the government provides funding on a 1:2 matching basis to manufacturers to establish smart production lines in Hong Kong. The funding limit is one-third of the total project cost or HK$15 million, whichever is lower.

The RFS initiative was launched in July 2020, and as of the end of January 2023, the RFS Vetting Committee has endorsed 31 applications from various sectors, including textiles and clothing, biotechnology, food manufacturing and processing, satellite manufacturing, construction, electronics, printing, nanofiber materials, equipment accessories, health products, and Chinese medicine. The total amount of funding provided through the RFS is approximately HK$270 million, with the companies contributing over HK$730 million in matching funds.

The global smart production market has been experiencing steady growth in recent years, owing to the increasing demand for automation in the industrial sector. The market is driven by the adoption of digital technologies such as the Internet of Things (IoT), artificial intelligence, robotics, and cloud computing in the production processes. These technologies facilitate the creation of smart production systems that can integrate production planning, quality control, supply chain management, and maintenance in a single system.

The growing awareness of the benefits of smart production, such as increased productivity, reduced costs, and improved safety, has resulted in a surge in investments in this market by organisations globally. The market is segmented by type, component, end-user industry, and region. Asia-Pacific is expected to dominate the market, with China, Japan, and South Korea leading the way. Other significant markets include North America and Europe, where the manufacturing sector is well-established.

This investment will allow Hong Kong to leverage its competitive advantages in food manufacturing and processing, and help the “Made in Hong Kong” brand to shine in both local and international markets.