The different way plants grow in the world’s first solar glasshouse is the subject of a new Murdoch University research project which will deploy custom-built autonomous robot technology. A researcher from Murdoch University will build bespoke robots to provide real-time monitoring of glasshouse plant growth.

The glasshouse horticulture industry is worth $30+ billion per annum and allows growers to extend crop seasons and yearly growing cycles. The industry will play an increasingly significant role in sustainable food production for a growing global population expected to hit 9.5 billion by 2050.

Earlier this year, a solar glasshouse developed by a WA-based smart building materials company, opened on the Murdoch campus. It is fitted with clear solar photovoltaic glass panels that let visible sunlight in while using invisible light to generate electricity. The PV panels generate power to run the glasshouse air-conditioning system, lighting, fans, louvres, blinds and reticulation system to provide an optimum growing environment.

Understanding how plants grow differently in the company’s glasshouse has proved to be very labour intensive with people required to monitor and regularly record germination rates and speed, plant height, leaf number, flowering time and fruit colour and yield.

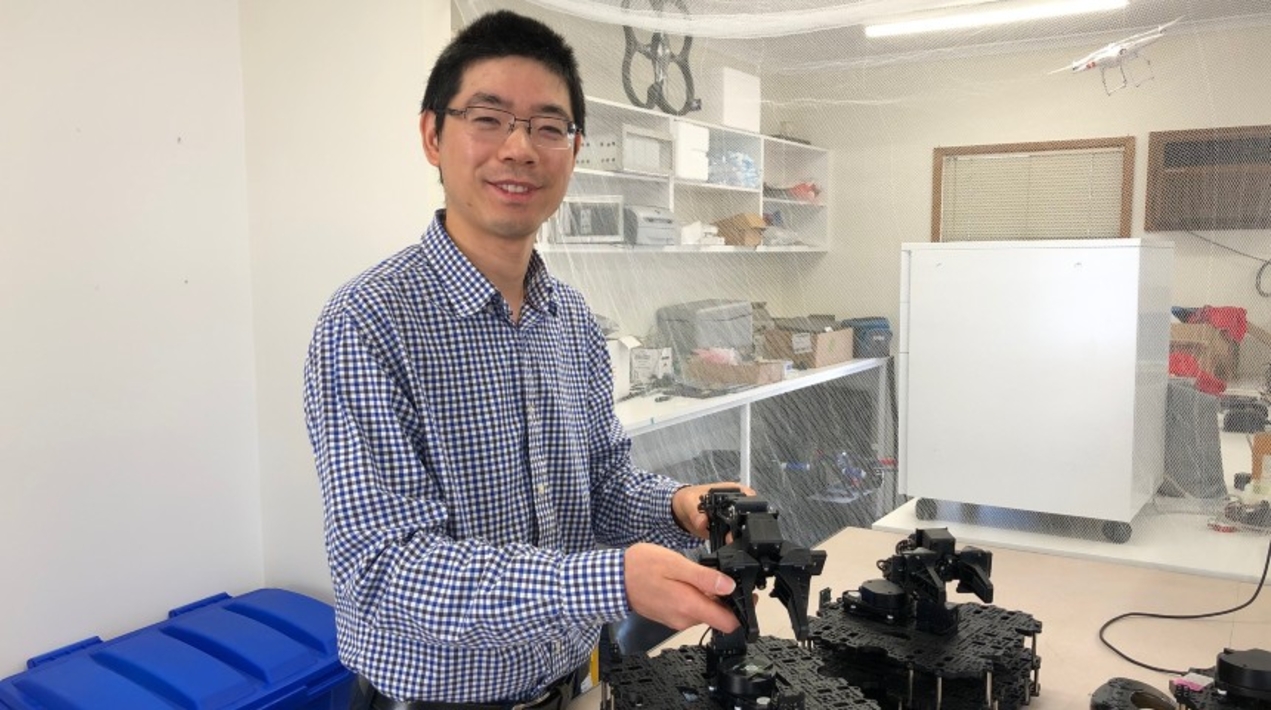

The Murdoch University Senior Lecturer in Electrical Engineering robotics and mechatronics expert from the Harry Butler Institute has secured a Research & Innovation Seed Grant to build bespoke intelligent autonomous robots to conduct real-time crop monitoring. He noted that these robots will be equipped with high-resolution cameras and sensors and will work day and night recording information on crop physiological characteristics and growing environments.

They will have a mobile base and be able to move around the room autonomously using modern advanced control and artificial intelligence-based navigation techniques. The cameras will continuously take images of the crops every certain period while the sensors will measure humidity, temperature and other changes in the environment.

They will have the capability to collect data on the way plants are growing, as well as valuable information like chlorophyll content, flowering time, harvest time, fresh biomass, the rate of CO2 entering and H20 exiting the leaves, and leaf health. This solar glasshouse facility is a world first. Everything is new and there’s a lot we don’t know about the impact of plant growth in this facility.

Anecdotally, we can see that compared to a standard glasshouse, some crops are growing faster in the company’s glasshouse and others are growing slower. The need is to understand why, get the data and then in the future, researchers might be able to build bespoke solar glasshouses that provide optimal growing conditions for different crops.

A Research Associate noted that as part of the research project, the company and standard glasshouses would be set up identically and monitored for six months. The bench position and rotation of benches, the amount of soil, water and fertiliser used, and the temperature will be exactly the same, he said. The robots will be doing exactly the same work at exactly the same time. The project was an example of a great collaboration between two Murdoch research institutes – Harry Butler and Food Futures.

The team would like to implement their theoretical research into practical areas and this is a very promising area. They also believe the technique could be further extended to many other industries, including real-time livestock monitoring, bushfire monitoring, mining inspection and autonomous agriculture. The research is one of 21 projects funded through the Research & Innovation Seed Grants for Murdoch early to mid-career researchers, with a total of $302,000 allocated.