An advanced approach to fixing wear damaged rails in remote locations using repair technology has been shown to be viable for large-scale use in neutron scattering experiments. Researchers from Monash University and ANSTO collaborated with engineers from the Institute of Railway Technology (IRT), the premier track and vehicle railway research centre in Australia as well as a sovereign heavy manufacturing company to develop a reliable and efficient laser-based rail repair technology.

The team used a nuclear technique at ANSTO’s Australian Centre for Neutron Scattering on the Kowari instrument to evaluate a laser cladding repair technique, which is an established method to repair high-value components in other industries on heavy haul rails. The method could increase the service life of rails and reduce maintenance time and costs, as repairing rails is preferable to replacing them.

The project’s industry partner, an ARC Linkage project partner, has vast experience and expertise in the use of laser cladding technology for manufacturing and repairs in the mining sector. Heavy haul rails repairs, however, present significant challenges to the manufactures as they cannot be performed in the controlled environment of the factory but rather need to be done in the remote areas of the Australian outback.

In research published in the Journal of Materials Processing Technology, they conclude that advanced laser technology could be used on heavy haul rails and that detrimental stresses could be reduced or mitigated from critical regions of the repair. With laser cladding, repairs are made by coating the damaged rail surface with a stainless steel or cobalt-based alloy in single or double layers using laser technology.

“Laser cladding can deposit these beneficial materials onto damaged areas but can also introduce or re-distribute residual stresses,” explained Taposh Roy, Monash PhD graduate, currently a Project Engineer Melbourne Metro Trains.

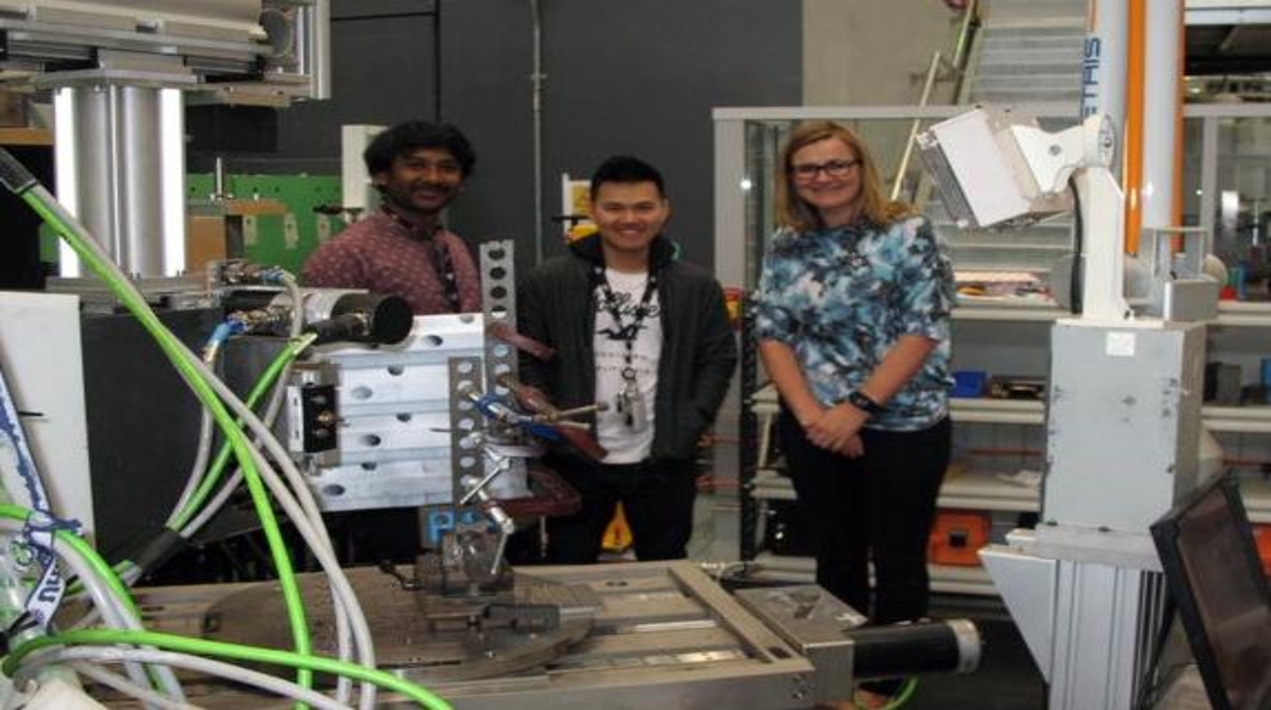

Investigators used neutron scattering on the Kowari strain scanner on a full-scale railhead to measure residual stresses created by the heat generated by the laser during the cladding deposition process (pictured above). As part of this, the team developed a new procedure to evaluate residual stresses in thick sections of full-scale cladded rails. Only neutrons can penetrate through the deep surface of the rail material, and measure full triaxial stress distribution non-destructively with little preparation.

To acquire measurements in small gauge volumes on a large path length through the steel, they made blind holes in the sample. Taking measurement at the middle of the two holes, also avoided a disturbance of local stresses. The team found that the application of a post cladding heat treatment significantly reduced the residual stresses from the surface and the subsurface of the cladded rails. The method appears to be superior to conventional arc weld based cladding methods, the most common technique to repair wear damage in rails.

“These successful in-house repair trials are very encouraging to explore further the application of this technology as a portable and mobilised unit, that can be deployed to address the rail maintenance problems in remote areas of Australia,” said Prof Anna Paradowska, Industry Engagement Manager, Australian Centre for Neutron Scattering and Conjoint Professor The University of Sydney.

About the Kowari – Strain Scanner

Kowari is a neutron scattering instrument. It is among the best residual stress diffractometers from neutron facilities around the world. Kowari started its operation for users in 2009. After a few years of operation, ANSTO sees a certain future of the instrument. In Australia, they are seeing the major usage being in problems with steel (and to a lesser extent aluminium-alloy) components, particularly welds.

This reflects the nature of Australia’s dominant industries: mining, power generation and transmission, shipbuilding, railways, construction (for instance of sports stadia), life extension of defence assets, and so on.

In Europe and the USA, there is a greater emphasis on higher value-added applications from the aerospace, defence and automotive industries, where composite and other unconventional materials are increasingly being used.