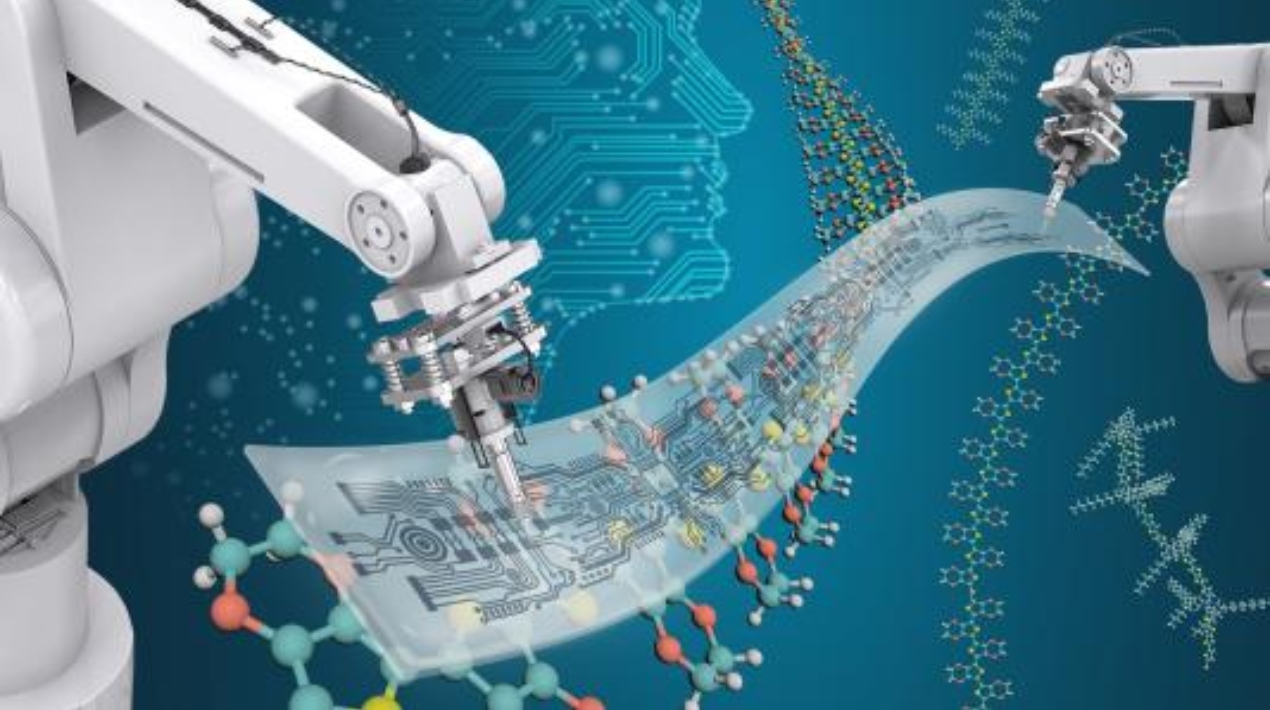

Scientists from the University of Chicago’s Pritzker School of Molecular Engineering and the United States Department of Energy’s Argonne National Laboratory have developed Polybot to automate specific laboratory procedures for studying electronic polymers. Thanks to Polybot, researchers can streamline their methods, conserve resources and increase productivity by focusing more on tasks requiring human intelligence.

This AI machine aims to enhance the next generation of bendable electronics utilised in wearable devices like smart glasses and watches. With the help of AI, wearable technology will be able to monitor health and provide targeted treatments for certain conditions more accurately.

The wearable tech will be made from electronic polymer, which is soft, flexible and conducts electricity. The Center for Nanoscale Materials (CNM) group focuses on polymer electronics to lessen the nation’s reliance on foreign oil and boost people’s health. Electronic equipment that may be recycled or decomposed is one such example.

“Just imagine the next generation of polymer electronics that’s not rigid anymore,” said Jie Xu, an Assistant Scientist at Argonne National Laboratory, and the Pritzker School of Molecular Engineering at the University of Chicago.

The software combines artificial intelligence (AI) and robotic automation. It is housed at Argonne National Laboratory at the Centre for Nanoscale Materials (CNM) of the DOE Office of Science. The time and money needed to complete challenging projects might be cut from years to months with the help of self-driving labs like Polybot.

Because scientists often synthesise polymer molecules to generate a solution with various ingredients to acquire the proper chemical structures for usage in electronics. After the solution is cooled, a thin layer of solid forms. Printed layers of varied compositions are the building blocks for many electronics.

The number of tweaks that can be done to get the required performance level is mind-boggling. They can include anything from incorporating novel materials into the production procedure to fine-tuning established practices. Such development can take a long time when using standard experimental techniques.

Artificial intelligence and robots are typically used in tandem on unrelated tasks in a Polybot experiment. A suitable polymer solution mix is chosen, synthesised, and printed as a very thin film at a predefined speed and temperature using an automated process. The technique checks the film’s quality by measuring its thickness and uniformity after sufficient time for the film to solidify. After that, numerous layers are stacked on top of one another and connected by electrodes to form the final device.

Polybot then evaluates the electrical performance of the device. Automatic data collection, machine learning processing, and input into the AI module constitute the entire process. The AI would then choose what sorts of testing are necessary. Polybot may respond to information from various sources, including user input and information found in the scientific literature.

A strong X-ray beam has already been used to examine the characteristics of electronic devices manufactured in Polybot. The Advanced Photon Source (APS) at Argonne, a DOE Office of Science user facility, was used for this purpose because of its equipment with a robotic sample handler. After the APS upgrade is finished in 2024, this link could be strengthened to make full use of the system.

According to Joseph Strzalka, a Physicist in Argonne’s X-ray Science division, “X-ray scattering analysis expands the Polybot’s characterization down to the molecular level, revealing information about the orientation and packing of the molecules that can help speed up the search for the best materials with optimal performance.”

While still in their infancy, they hope to use AI and robotics to increase productivity, decrease expenses, and quicken the pace of scientific discovery. Xu states that the applications of Polybot extend far beyond medical devices. Two examples are new climate change sensors and materials for “brain-like” computers. Current lithium-ion batteries require a flammable liquid electrolyte, which new solid electrolytes might replace.