Two-dimensional materials, which are made up of just a single layer of atoms, can be packed closer together than conventional materials, leading to the development of faster and more effective transistors, solar cells, LEDs, and other electronic devices.

The heat these next-generation electronics produce while in use is one problem preventing their widespread use. Since the materials in 2D devices are compressed so closely together, they can heat up to twice as much as conventional electronics, which typically reach temperatures of about 80 degrees Celsius. The device could be harmed by this temperature increase.

The fact that scientists don’t fully comprehend how 2D materials expand when temperatures rise only makes the issue worse. The thermal expansion coefficient (TEC), which refers to a material’s propensity to expand as temperature rises, cannot be measured using conventional methods because the materials are optically transparent and extremely thin.

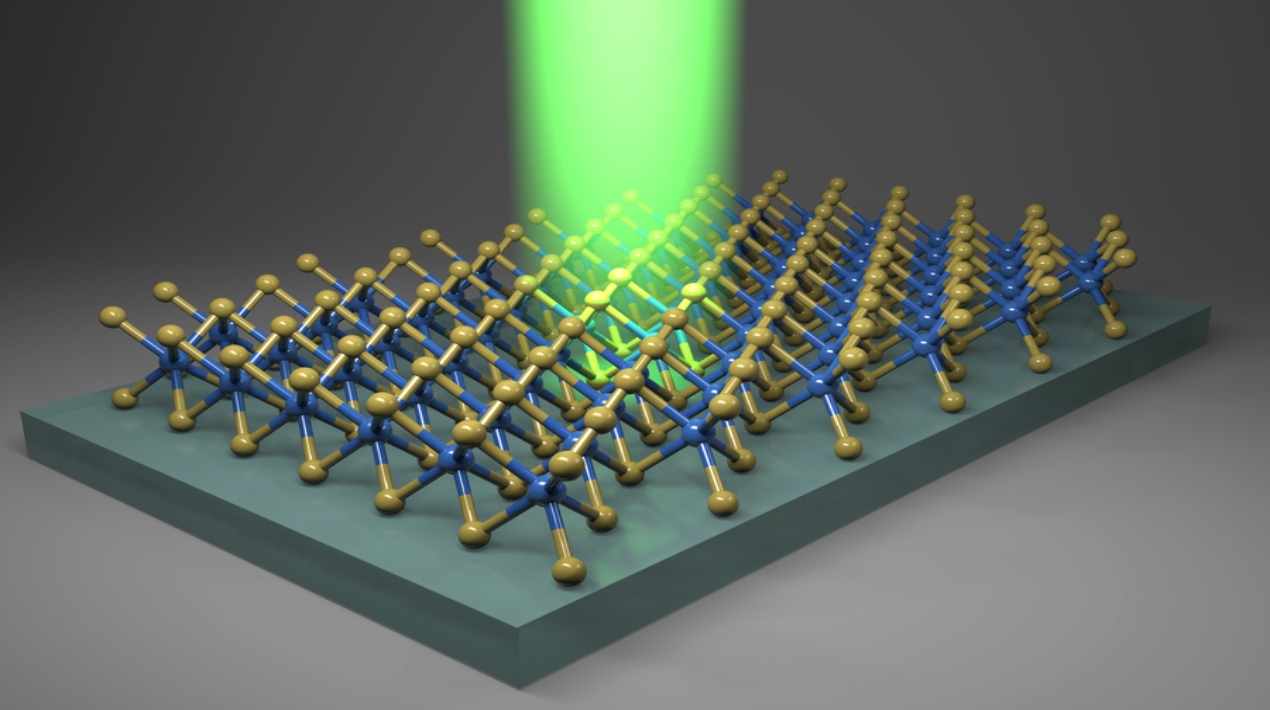

They use laser light to track the vibrations of the material’s atoms rather than directly measuring how the material expands. They can accurately determine a 2D material’s thermal expansion coefficient by taking measurements of it on three different surfaces, or substrates.

The results of the new study demonstrate the method’s high degree of accuracy, matching theoretical calculations exactly. The method confirms the much smaller range than previously believed in which the TECs of 2D materials fall. This knowledge might be useful to engineers creating electronics for the future.

Researchers gave engineers a lot of material flexibility for selecting the bottom substrate when they are designing a device by confirming this narrower physical range. To only reduce thermal stress, they don’t even need to design a new bottom substrate. This has significant ramifications for the electronic device and packaging industries, according to researchers.

Standard tools aren’t sensitive enough to directly measure the expansion of 2D materials because they are so small—possibly just a few microns in size. Additionally, because the materials are so thin, they need to adhere to a substrate like copper or silicon. Thermal stress results from the expansion of the 2D material and its substrate, which differ in TEC, when temperatures rise.

For example, if a 2D material is bonded to a substrate with a higher TEC, the substrate will expand more than the 2D material, stretching it, when the device is heated. As a result, it is challenging to determine a 2D material’s actual TEC because the substrate affects its expansion.

By concentrating on the atoms that make up the 2D material, the researchers were able to overcome these issues. A material expands when heated because the atoms vibrate at a lower frequency and move further apart. By hitting the material with a laser, a method known as micro-Raman spectroscopy is used to measure these vibrations. The interaction between the laser light and the vibrating atoms allows for the detection of their vibrational frequency.

But as the substrate grows or shrinks, the vibrations of the atoms in the 2D material change. To focus on the material’s intrinsic properties, the researchers needed to decouple this substrate effect. On three different substrates—copper, which has a high TEC, fused silica, which has a low TEC, and a silicon substrate with numerous tiny holes—they measured the vibrational frequency of the same 2D material to achieve this. Because the 2D material hovers above the holes on the latter substrate, they can measure these minuscule areas of freestanding material.

The researchers want to use their approach with a lot more 2D materials in the future, perhaps compiling a database of TECs. They also intend to measure the TECs of heterogenous materials, which combine various 2D materials, using micro-Raman spectroscopy. Additionally, they want to understand the underlying causes of why 2D materials’ thermal expansion differs from that of bulk materials.